Here at The Laser Cutting Co., we are committed to continuously improving the quality of our services and always go above and beyond to develop innovative solutions to improve our range of specialist steel profiling facilities. As leading experts in sub-contract metal fabrication and cutting services, we understand more than most how important quality structural steel fabrication is, which is why we only ever strive for excellence.

With over 40 years of combined laser profiling industry experience, we have taken every opportunity to expand and broaden our expertise to ensure our customer’s satisfaction every time. From FlowDrilling and Tapping to Smart Design Production and Sheet Metal Bending, our comprehensive range of steel and metal profiling services and the latest technology are designed to meet any metal profiling requirements – no matter how particular.

Structural steel fabrication can bring various challenges and requires a great level of skill to master. Our team are experts in their fields and have dedicated several years to perfecting and honing their craft. However, the question for some remains; what exactly is structural steel fabrication? Here’s The Laser Cutting Co.’s guide to structural steel fabrication, its benefits, and applications.

What Is Structural Steel Fabrication?

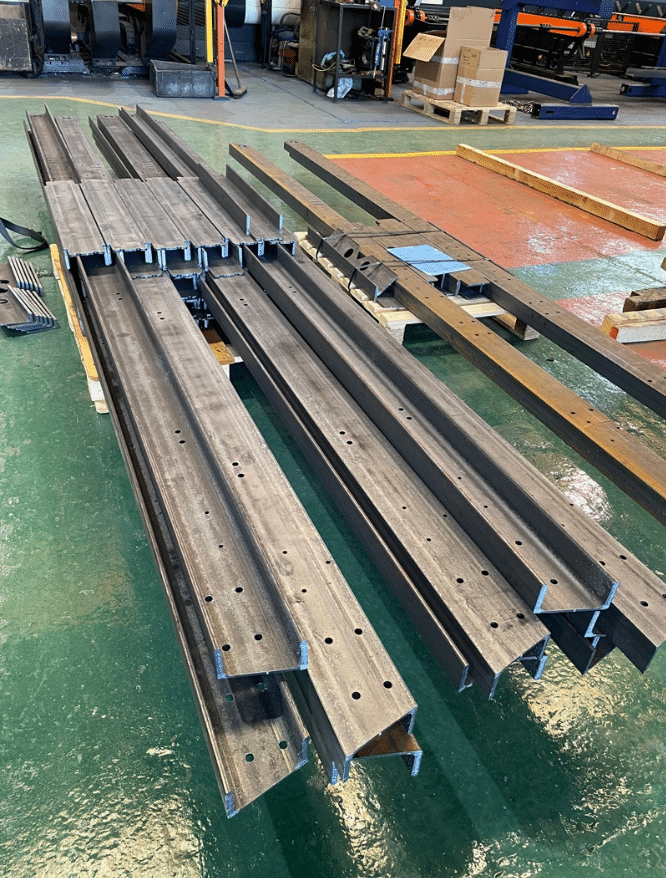

A multifaceted process, structural steel fabrication is the method of cutting, bending, and assembling steel parts; all to create a final structural product. Fabricated steel has a plethora of uses across a variety of industries, including construction, manufacturing, energy, and much more. Commonly found in buildings, industrial equipment, construction tools, and more, structural steel is an essential facet required for a huge range of construction projects.

Fabrication Process Of Structural Steel

Often a complex and arduous process, structural steel fabrication requires fervent planning and preparation by our professional engineers before any further work can be done. Once the appropriate method of profiling has been agreed upon and initial design drawings have been produced, it is then that we begin processing the steel to the client’s specific requirements.

Offering a comprehensive range of in-house steel cutting and profiling services alongside sister company Charles Day Steel, we understand more than most the complexities of accurate steel profiling.

With all this being said, here are our main stages for structural steel processing…

1. Cutting

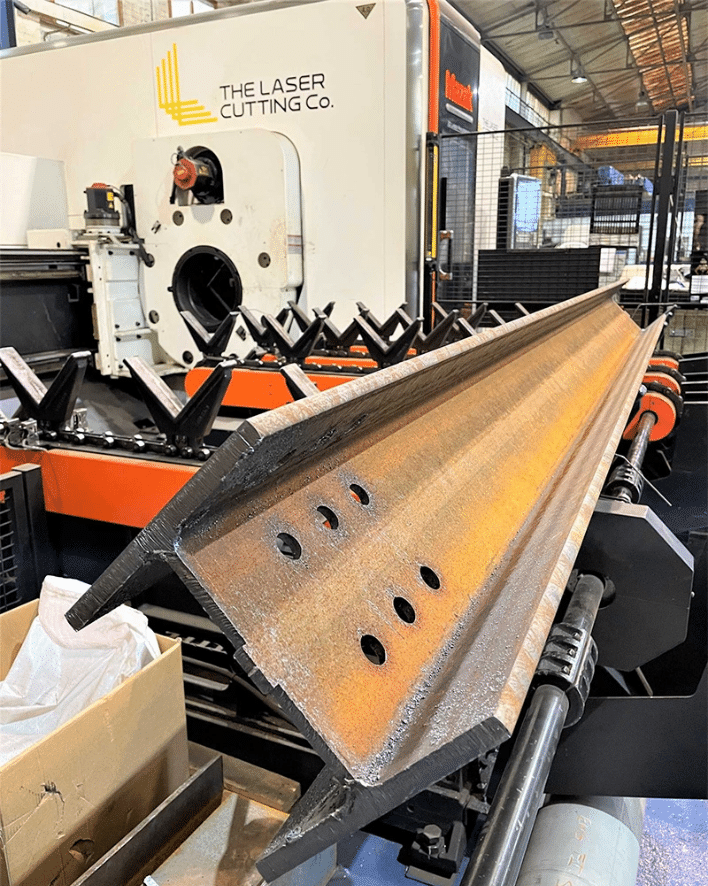

Once final designs are agreed upon for the finished product, our fabricators take immense care to cut the required steel members, using a host of methods such as flat and tube, Laser Cutting, Flame Cutting, Waterjet Cutting, and Plasma Cutting – the method chosen is dependent on the desired final product. Extreme caution, strict quality control, and attention to detail are always at the forefront of everything we do here at The Laser Cutting Co.

2. Bending

With in-house sheet metal bending facilities, our expert steel profilers here in Sheffield utilise the very best in metal bending technology; using our bespoke suite of CNC Brake Press Machines to procure expertly accurate parts for assembly.

3. Assembling

Once the required parts have been bent and quality checked, the separate steel elements are brought together to create the final product; this usually involves welding and/or bolting.

4. Cleaning

Next, the steel needs to be cleaned of any residual debris remaining from the previous stages. Common methods such as surface rusting and machine blasting are often used to prepare these parts for painting.

5. Painting

In the last stage of the structural steel fabrication process, anti-rust paints are applied, alongside normal paints and coatings for the final few touches. This is to prevent corrosion caused by the weather and environment.

What Are The Benefits Of Structural Steel?

The benefits of structural steel prove to be excellent across a plethora of industries and have a host of advantages when compared to other metallic options. Some benefits include…

Low Maintenance

Steel in general requires much less maintenance in comparison to other metal options, is easy to repair, and is extremely durable.

Low Cost

A relatively inexpensive material, steel is very affordable, whilst still being strong and durable.

Environmental

Endlessly reusable, steel can be recycled and repurposed. Not only this, but steel production requires far less energy compared to other metals, and generates significantly less carbon dioxide.

Strength

Lightweight and one of the strongest metals available, steel is a highly durable option for fabrication.

Malleable

Structural steel is incredibly malleable and great for forming complex configurations to suit even the most complicated of projects.

Appearance

Steel provides a high-quality finish, and gives projects an enhanced appearance.

Prefabrication Abilities

Prefabrication ensures less work needed to be done on-site and is particularly useful for projects that need to be completed in a short amount of time.

Our Structural Steel Fabrication Services

A cross-industry solution to a multitude of construction requirements, from manufacturing and construction industries to mining, automotive, and aerospace industries – structural steel is the crux of the majority of fabrication projects.

For more information, get in touch with the team at The Laser Cutting Co. today, or take a look at our TLCC Brochure today.