Laser cutting is a precise and efficient method of cutting various materials using a focused beam of light. This advanced technology has become a cornerstone in modern manufacturing due to its ability to produce intricate designs with high accuracy, minimal waste, and exceptional edge quality.

The laser cutting process involves directing a high-powered laser beam to melt, burn, vaporise or blow away material, leaving an edge with a high-quality surface finish. The versatility and precision of laser cutting make it indispensable across a variety of industries and applications.

Types of Laser Cutting

Laser cutting can be categorised into different types based on the laser source and application. The primary types of laser cutting include:

CO2 Laser Cutting

Mechanism: Uses a gas mixture primarily composed of carbon dioxide to generate the laser beam.

Advantages: Offers high cutting speed and efficiency for non-metal materials, making it suitable for applications in signage, packaging, and textiles.

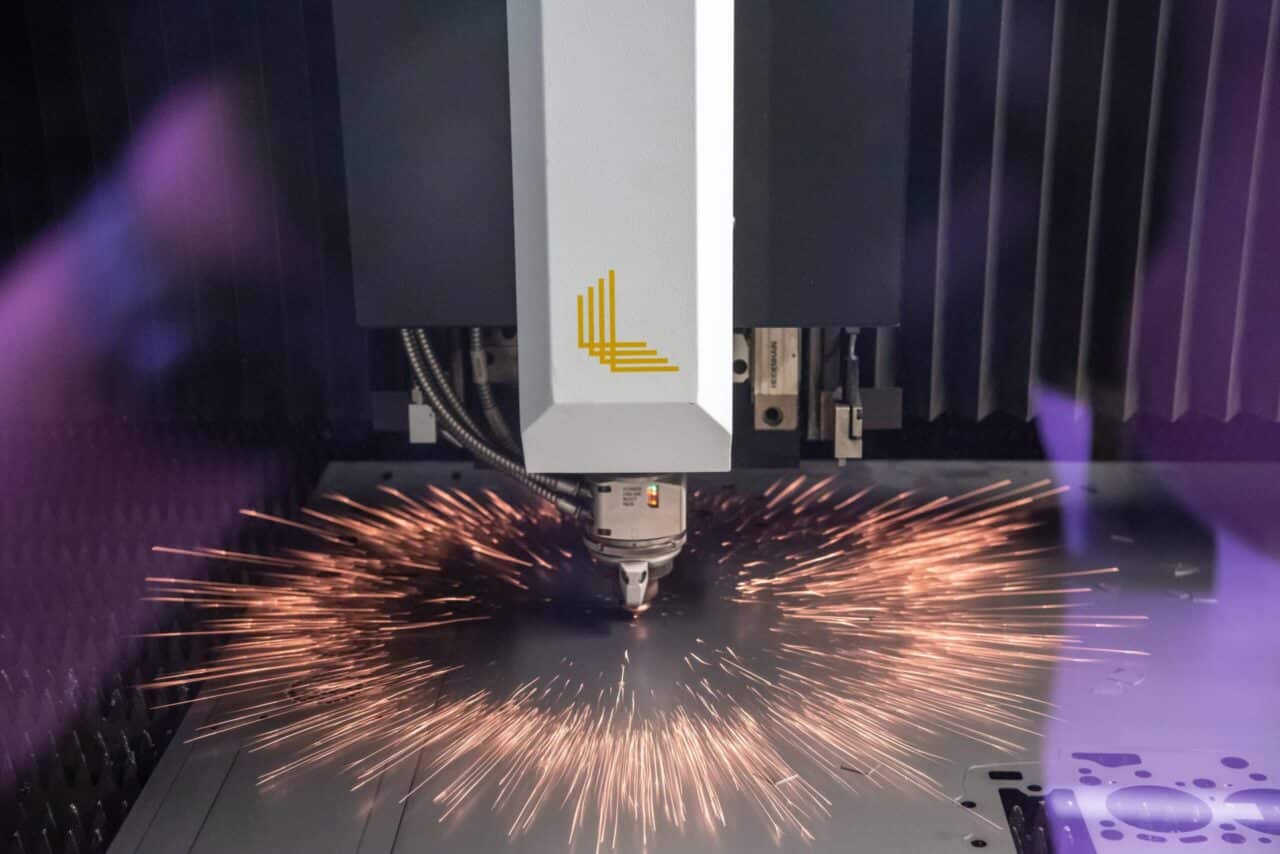

Fibre Laser Cutting

Mechanism: Uses a solid-state laser generated from a seed laser and amplified through glass fibres.

Applications: Best suited for cutting metals, including steel, stainless steel, aluminium, brass and copper.

Advantages: Provides high precision and speed, lower maintenance costs, and higher energy efficiency compared to CO2 lasers. It is particularly effective for cutting reflective materials.

Nd and Nd Lasers

Mechanism: Uses a crystal medium of neodymium-doped yttrium aluminium garnet (Nd) or just neodymium (Nd).

Applications: Primarily used for high-energy applications such as welding, drilling, and engraving, as well as cutting metals and ceramics.

Advantages: Suitable for tasks requiring high power density and short pulse durations, making it ideal for detailed and precise work.

How Does Laser Cutting Work?

Laser cutting involves a series of precise and controlled steps to achieve accurate cuts:

Generating the Laser Beam

Laser Source: The process begins with generating a laser beam from a source such as CO2, fibre, or Nd. The type of laser source determines the material compatibility and efficiency.

Amplification: In fibre lasers, the beam is amplified through fibre optics, whereas CO2 lasers use a gas-filled tube, and Nd lasers use a crystal medium.

Guiding the Beam

Optics: Mirrors and fibre optics guide the laser beam from the source to the material surface. The path of the beam is precisely controlled to ensure accuracy.

Beam Delivery: The beam is directed to the cutting head where it is further refined and prepared for focusing.

Focusing the Beam

Lenses: High-precision lenses focus the laser beam to a fine point, increasing its intensity. The focal point is critical as it determines the cutting efficiency and quality.

Spot Size: The focused beam has a very small spot size, typically less than a millimetre in diameter, which allows for fine, detailed cuts.

Cutting the Material

Melting/Vaporisation: The focused laser beam melts or vaporises the material along the cutting path. The CNC program controls the movement to follow the desired design.

Assist Gas: An assist gas, such as oxygen, nitrogen, or air, is often used to blow away molten material and debris from the cut, enhancing the quality and speed of the process.

Laser Cutting Applications

Laser cutting’s precision and versatility make it ideal for a broad range of applications across multiple industries:

- Manufacturing: Component fabrication and tooling

- Automotive: Parts production and prototyping

- Aerospace: Lightweight components and precision cutting

- Electronics: Circuit boards and enclosures

- Jewellery: Detailed designs and custom pieces

Our Laser Cutting Services

At The Laser Cutting Co., we offer a comprehensive suite of laser cutting services designed to meet the diverse needs of our clients. Our state-of-the-art facilities and extensive experience ensure top-notch results for projects of all sizes and complexities.

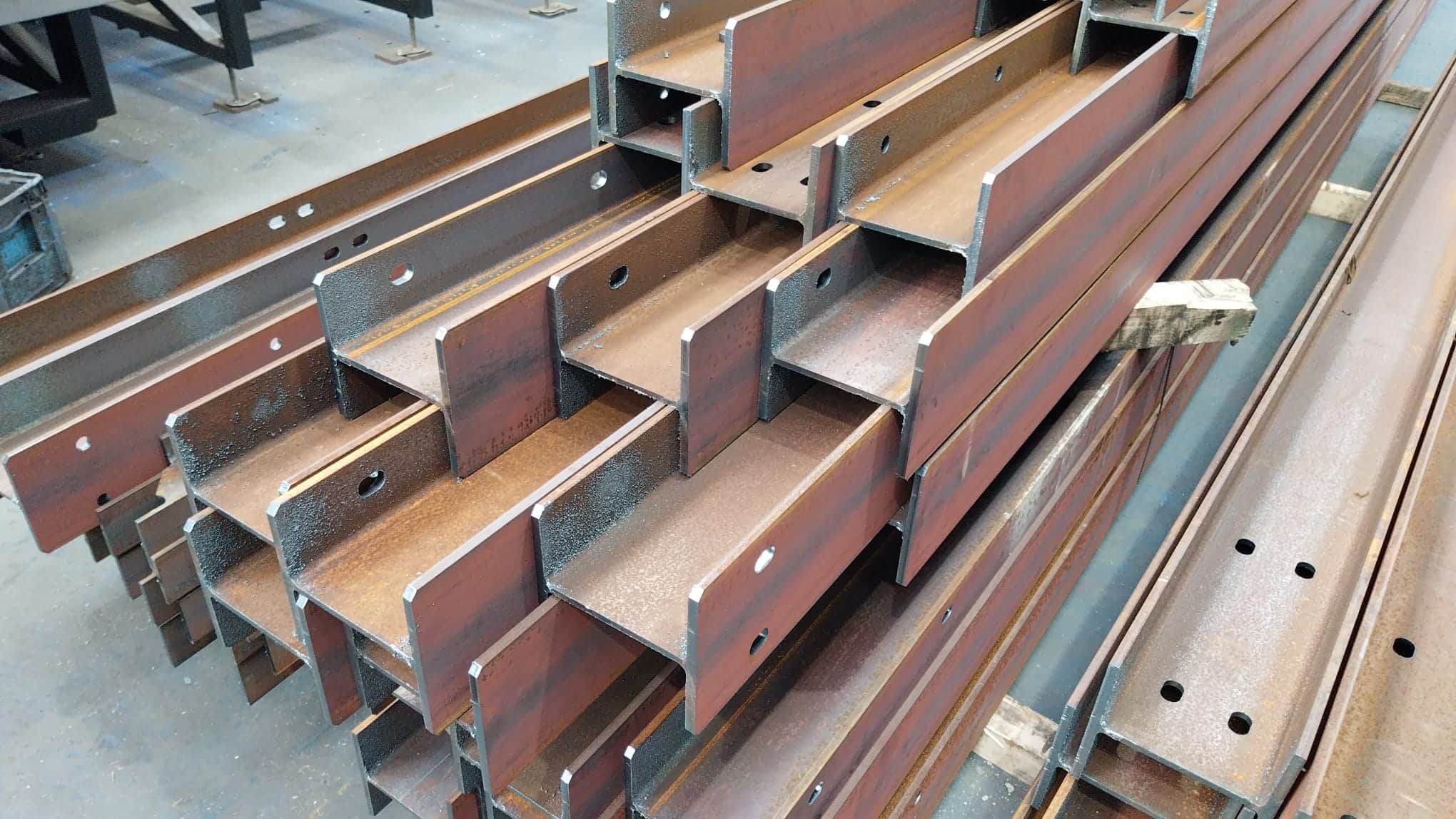

Sheet Metal Laser Cutting

Precision: Achieving a cutting tolerance of ±0.25mm, our laser cutting services deliver unparalleled accuracy.

Capabilities: Handling sheet metal sizes up to 2000 x 4000mm and thicknesses up to 50mm. For larger projects, our sister site accommodates sheets up to 6000 x 2500mm.

Efficiency: Reduced waste and rapid lead times with intricate cutting and fine contouring.

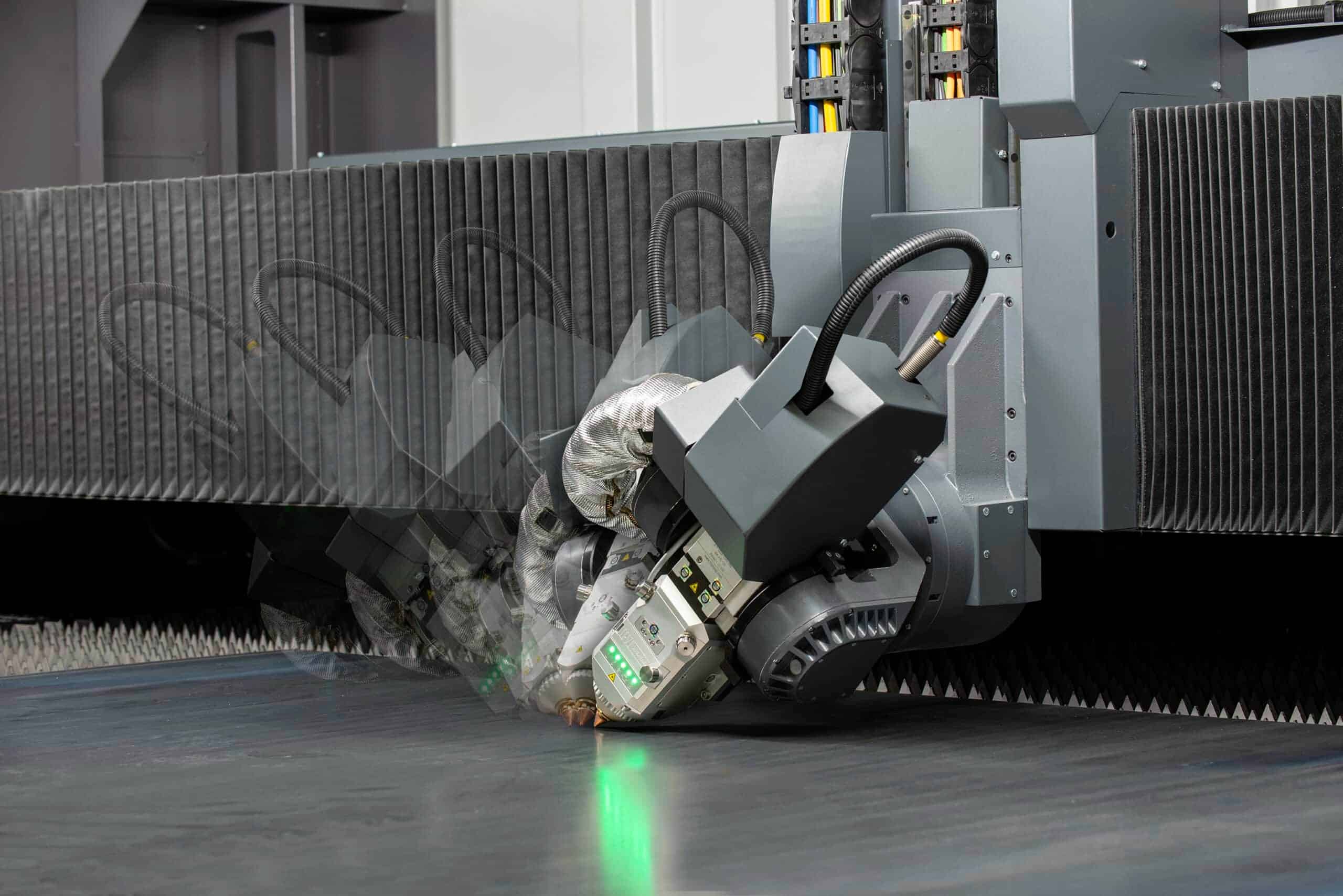

Tube Laser Cutting

Multi-Axis Cutting: Advanced 3D cutting capabilities for tubes and profiles, reducing the need for welding and assembly.

Optimisation: Supports part design optimisation for efficient manufacturing, minimising material usage and assembly requirements.

Lead Times: Rapid turnaround due to our specialised profiling service and experienced in-house design team.

Bevel & Countersink

Automated Technology: Industry-first laser cutting technology producing up to 50° bevels on both outer and inner contours.

Efficiency: Eliminates manual weld prep, suitable for small and large volume projects.

Capabilities: Available for sheet metal up to 30mm thick.

Flow Drilling & Tapping

Strong Fixings: Creating strong fixings without fasteners, suitable for various metals including mild steel, stainless steel, copper, brass, bronze, and aluminium.

Cost Reduction: Significantly reduces production costs and improves efficiency.

Materials: Handles material thicknesses from 0.5mm to 10mm, with thread sizes ranging from M2 to M30, including BSP sizes.

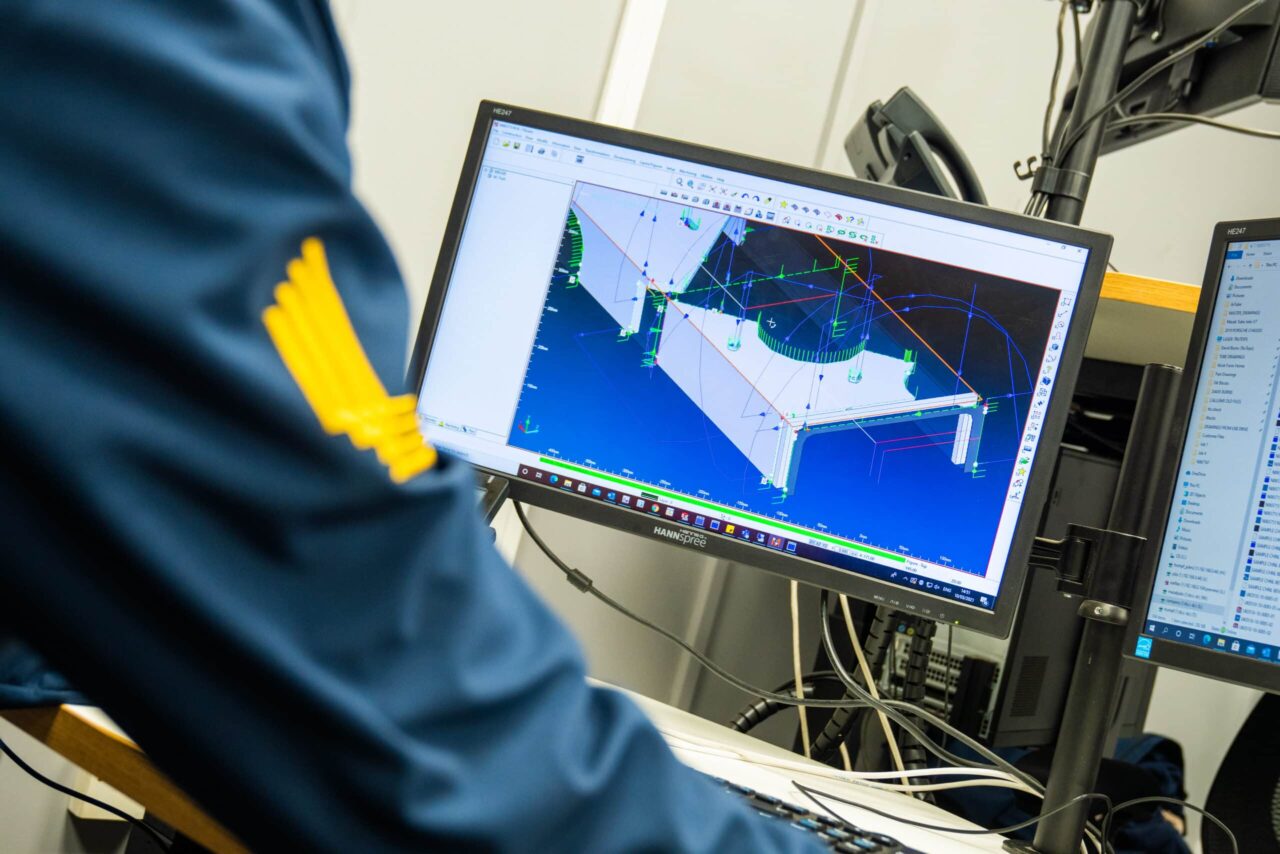

Smart Design Production

Part Optimisation: Optimises part designs for efficient manufacturing, reducing material waste, and simplifying assembly processes.

Cost Savings: Achieves up to 50% cost savings by reducing component volume and overall complexity.

Innovative Techniques: Uses techniques such as self-jigging parts, part folds, and slot and tag for efficient production.

Trust The Laser Cutting Co. for Professional Laser Cutting Services & Technology

Laser cutting is a transformative technology that offers unmatched precision, efficiency, and versatility. Whether you need intricate sheet metal designs, optimised tube profiles, or assembly-ready parts, laser cutting provides a reliable solution.

At The Laser Cutting Co., we leverage the latest technologies to deliver high-quality laser cutting services, ensuring rapid lead times and competitive pricing for projects of all sizes. For further information and guidance, contact our team today.