Within the modern market, the demand for new products and solutions is continuously rising. Developing products within rapid turn-around times has become necessary to keep up with existing competitors and consumer requirements within fast-paced sectors. Oftentimes, product prototypes remain in limbo during developmental stages due to constant design iterations on slow systems, which leads to significant backlogs within the production pipeline.

Laser cutting has proven to provide revolutionary benefits across an extensive range of industries, and it has been fundamental in developing prototypes with integrated CAD software. At The Laser Cutting Co., we are market leaders in laser cutting and smart design production. Our ethos strives to create exceptional quality, economical solutions and optimise downstream processes for all client projects, regardless of complexity. We understand the importance of delivering tangible results to investors and customers, and we believe laser cutting guarantees exceptional performance in prototyping.

How Does Laser Cutting Assist in Prototyping?

Prototyping provides invaluable developmental data, creating physical and functional designs before investing in the final product. This is necessary because the production of an untested product can lead to a mass loss in sales if it cannot meet its intended purpose. Traditionally, prototyping utilises sketches or computer models, which can be time-consuming due to the sourcing of materials and project scale.

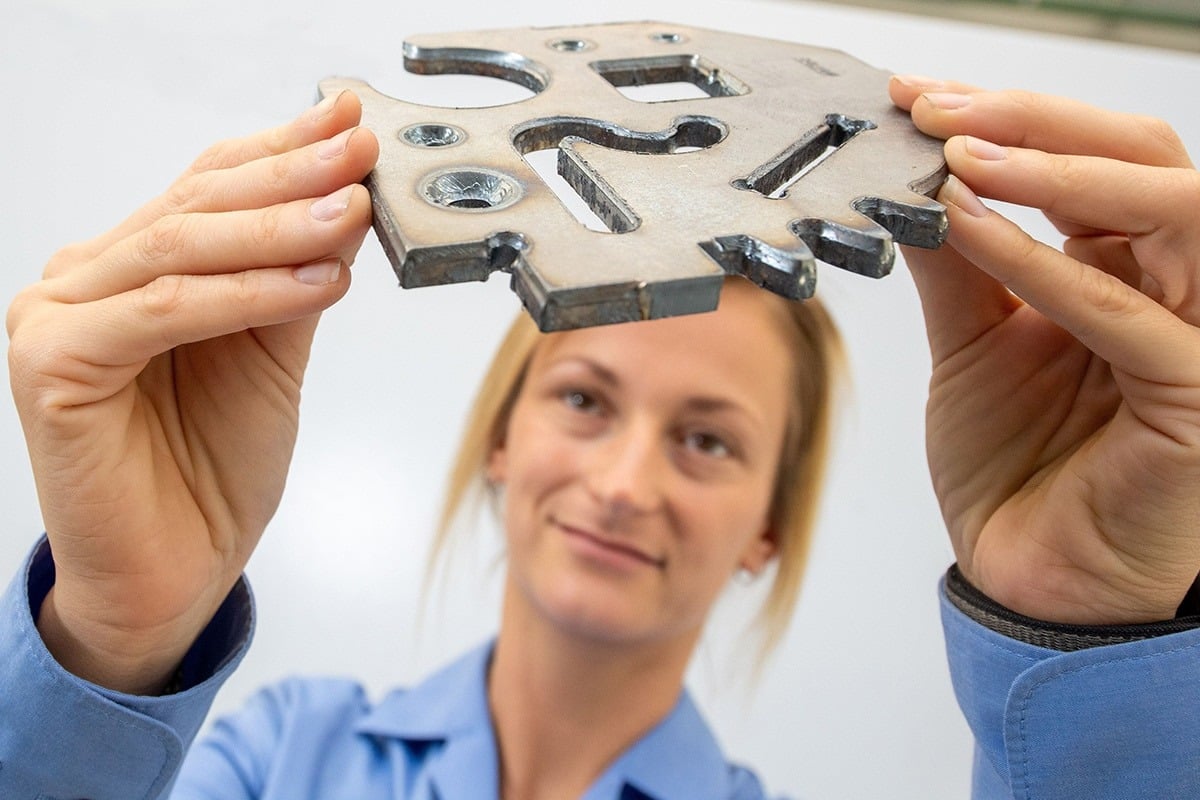

3D printing has been instrumental in creating prototypes for various industries, but often falls short due to size limitations, knowledge of use and slow processes. The integration of CAD machines and laser cutting mitigates these issues since the machine beds are equipped to produce larger prototypes under strict tolerances.

Inputting data into smart CAD systems eliminates the margin of error as the technology generates consistent quality for even the most intricate requirements. This allows for effective product testing as the machines have millimetre precision and can run fully automated. Laser-cut prototypes deliver rapid development, ensuring products hit the market sooner and expedite prototypes due to their refined processes and automation.

The Advantages of Laser Cut Prototypes

Rapid Results

Laser cutting is renowned for its swift production, generating prototypes in short lead times compared to the weeks that can potentially occur from traditional methods. This ensures exceptional performance for industries that require rapid prototyping within stringent tolerances.

Quality Precision

Prototyping must effectively represent the final design, which means adhering to exact measurements for product testing. Laser cutting is millimetre precise, which results in an accurate reflection of how components, fixtures and product functionality will work together.

Versatility

Laser cutting is highly effective in cutting several metals, plastics, wood and textiles, which makes it a powerful and versatile tool. With the implementation of digital designs, there is scope for swift adjustments to be made throughout the prototyping process.

Economical

Due to the precise accuracy of laser cutting, it is effective at mitigating material waste and any additional moulds or tools required. This establishes a cost-effective solution for prototyping, ensuring that companies can retain quality while minimising expenses.

Industries that Utilise Rapid Prototyping

Automotive

The automotive industry is reliant on rapid prototyping for interior and exterior components. All aspects of a vehicle undergo prototyping, such as the structure, mechanical parts, and design features to guarantee safety.

Aerospace

The aerospace industry focuses heavily on streamlining processes and finding effective solutions that meet safety standards. The role of laser cutting within aerospace provides engine components, structural design, turbines and more, to meet demanding requirements within set budgets.

Electronics

Laser cutting can cut delicate and intricate parts for the electronics industry. This is especially beneficial for testing the functionality of circuit units, complex elements and exterior casings.

Trust The Laser Cutting Co. for Exceptional Laser Cut Prototyping

Laser cutting provides undeniable advantages for sectors that require rapid prototyping, putting products on the consumer market within desirable timeframes. The Laser Cutting Co. invests in innovative smart technology that guarantees superior quality prototypes. Our smart design production optimises downstream processes from our expert in-house design team, eliminating customer rejects with a 50% cut in production time.

Our dedicated team can assist with all aspects of the project, from sourcing material type, thickness, desired cut, and project complexity. For further guidance and bespoke advice for your prototype requirements, contact a member of our experienced team.