The Future of Laser Cutting Technology

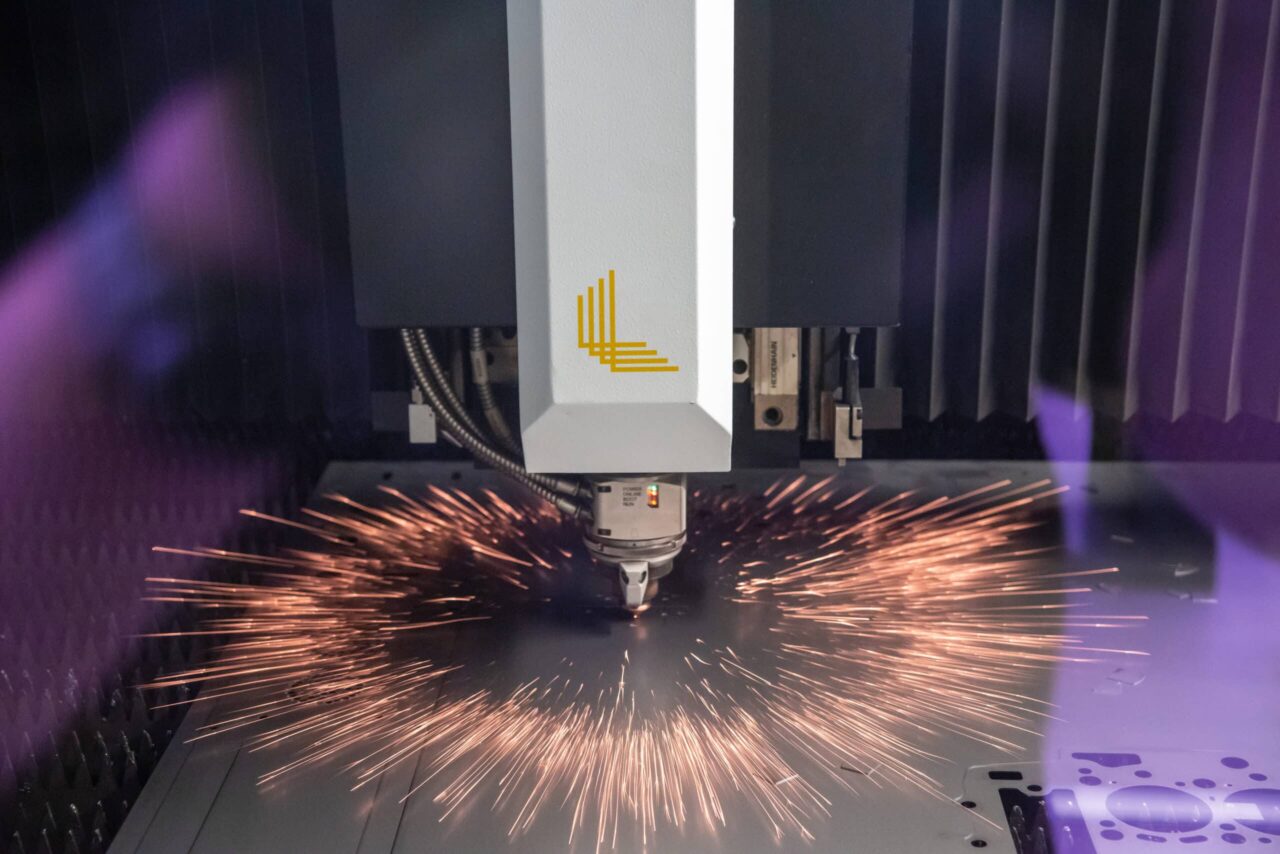

Since the 1960s, laser cutting technology has transformed industrial manufacturing, delivering efficient, cost-effective, and high-accuracy results across a spectrum of high-demand industries. At Laser Cutting Co. we aim to forge a bright future for businesses and manufacturers alike through technological advancements – Today, we’re discussing how evolving technology drives the new wave of the industrial revolution.

Current Advancements in Laser Cutting

Fibre lasers are at the forefront of innovative laser cutting technology, demonstrating notable energy efficiency and promising ongoing advancements. They offer faster processing speeds, unlike CO2 lasers, and are remarkable for their power, cost-effectiveness, precision, and reduced maintenance requirements.

As technology advances, the capability for higher-wattage lasers has improved, enhancing cutting processes and enabling the handling of more complex and diverse designs. This progress is particularly advantageous for industries that utilise heavy machinery, such as shipbuilding.

The Era of Automation and Robotics

Laser-cutting automation has become essential in the industry. Integrated automation systems, including robotics, CNC (computer numerical control) machines, and advanced software, have streamlined production processes. These systems minimise the need for human input by effectively collecting real-time data and fully automating tasks such as loading, unloading, and design execution. This results in near-zero error margins, exceptional consistency, and advances towards eco-friendly laser cutting by significantly reducing waste.

As we enter the Fourth Industrial Revolution, the use of AI in these systems is becoming increasingly natural. Emphasising IT solutions and smart technologies, this evolution aims to meet demand, enhance worker safety, and address the environmental impact of laser-cutting technology.

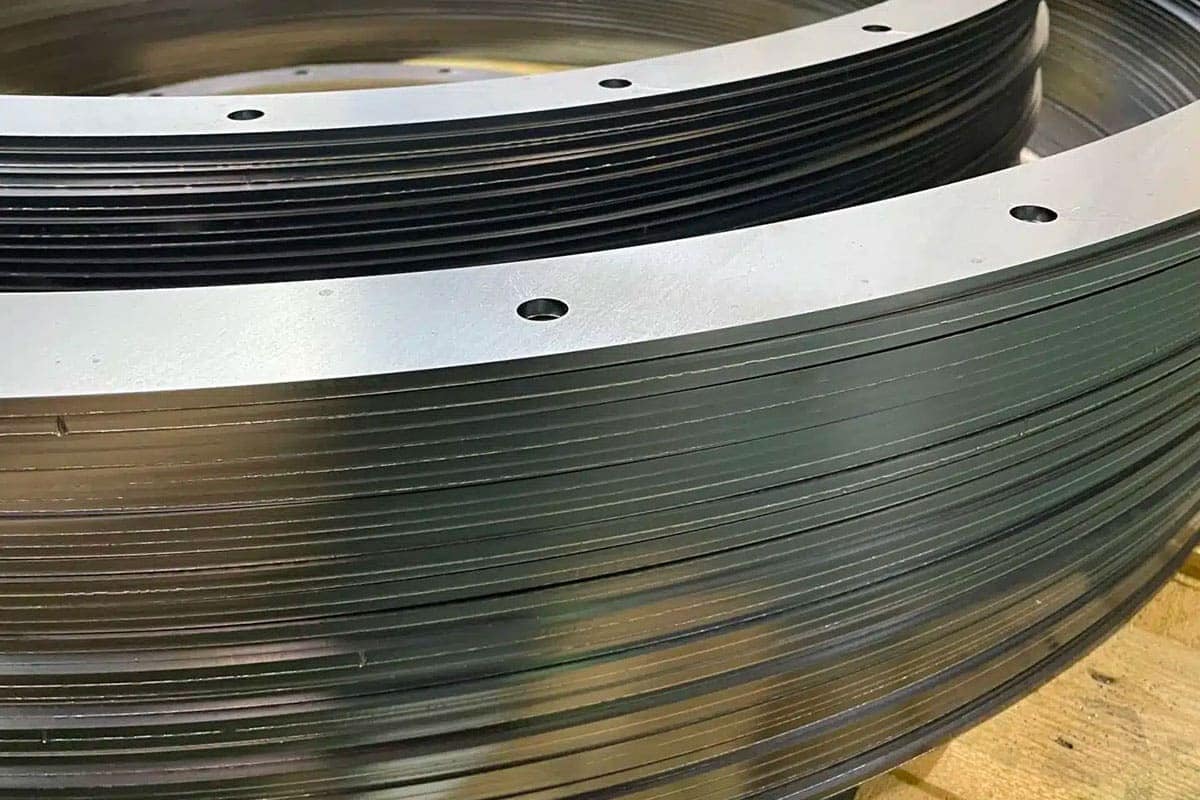

Expanding Material Capabilities

What was once dominated by metal cutting has now expanded to include various advanced materials, including organic materials, composites, plastics, and ceramics. This versatility has become an invaluable resource for innovation and design across businesses worldwide; and is especially beneficial for rapidly developing industries, such as the medical field, where it provides medical devices with exceptional precision and quality.

Laser Cutting’s Sustainability Future

Throughout the laser cutting process, the focus on enhancing sustainability to address environmental concerns for manufacturers is frequently discussed. In the modern era, filtration systems within machines have significantly improved, effectively reducing harmful emissions. Additionally, fibre lasers, which utilise a concentrated beam of light through a doped optical fibre, offer an energy-efficient alternative, providing a more environmentally friendly option.

Current Challenges in Laser Cutting

There will always be challenges as new technology is introduced, despite the exciting prospects ahead. Key concerns include:

Improving Workplace Safety

Skilled workers, especially laser operators, remain invaluable in the manufacturing process, even with advancements in automation. As technology evolves, so does our knowledge and ability to enhance safety. This requires ongoing improvements to safety protocols, including training and the adoption of new tools.

Cost-Effectiveness for Smaller Businesses

Investing in advanced technology can be challenging for smaller, locally run businesses. Often, outsourcing to manufacturers that offer a range of laser cutting services at competitive prices can be a more cost-effective solution.

Demand for Skilled Workers

As new laser cutting technologies become the industry standard, the demand for skilled workers who understand best practices also increases. Fortunately, augmented reality (AR) and virtual reality (VR) technologies offer innovative solutions for training, providing near hands-on experience for both new trainees and existing employees.

Future Laser Cutting Trends

Laser cutting technology will only continue to expand with some exciting new prospects on the horizon. Here are a few notable trends for the market:

AI Integration

Artificial Intelligence will drive the industry, enabling incredibly precise parameters and maximising efficiency in the workload for manufacturers.

Enhanced Efficiency and Cost-Effectiveness

Lasers will become more energy-efficient and powerful at reduced costs, broadening their range of capabilities.

Growing Role Across Industries

Laser cutting’s role within various industries will continue to grow, demonstrating its value even in the fashion market, and increasing accessibility to many more. Most notably, it has been instrumental in providing groundbreaking contributions to healthcare and aerospace components, demonstrating the advantages of laser cutting.

Hybrid Laser Cutting

The ability to combine different processes through hybrid laser cutting will allow for more diverse projects and materials. Combined with 3D laser cutting, which is steadily increasing in popularity, it will enable more intricate designs with limitless possibilities.

What’s next?

The laser cutting industry thrives on new technology that supports businesses worldwide and will continue to evolve with limitless creativity. At Laser Cutting Co., we pride ourselves on delivering reliable, high-quality results that can transform your business.

We utilise the latest technology and collaborate with you throughout every step of the process, we can handle your projects of any size. To explore how the future of laser cutting can benefit your business at our competitive rates, get in touch with a member of our team today.