When it comes to industrial manufacturing, efficiency, precision and versatility are paramount. At The Laser Cutting Co., we continuously invest in the latest laser cutting technologies to stay at the forefront of the industry. One of our most significant advancements is the integration of multi-axis tube laser cutting machines, a game-changer in the realm of metal profiling and fabrication. But what exactly sets multi-axis tube lasers apart, and why should manufacturers consider this technology for their projects?

Enhanced Design Possibilities

Multi-axis tube lasers open up a world of new design possibilities. Unlike traditional 2D laser cutting, which is limited to flat sheets, multi-axis tube lasers can cut complex geometries and intricate designs on tubular and structural sections. This capability allows for more innovative and efficient designs, enabling manufacturers to optimise parts for performance and aesthetics.

For instance, our state-of-the-art tube laser cutting machines support advanced part optimisation, reducing the number of components required for assembly. By minimising welding and simplifying designs, we help our customers achieve more efficient manufacturing processes.

Increased Efficiency and Reduced Costs

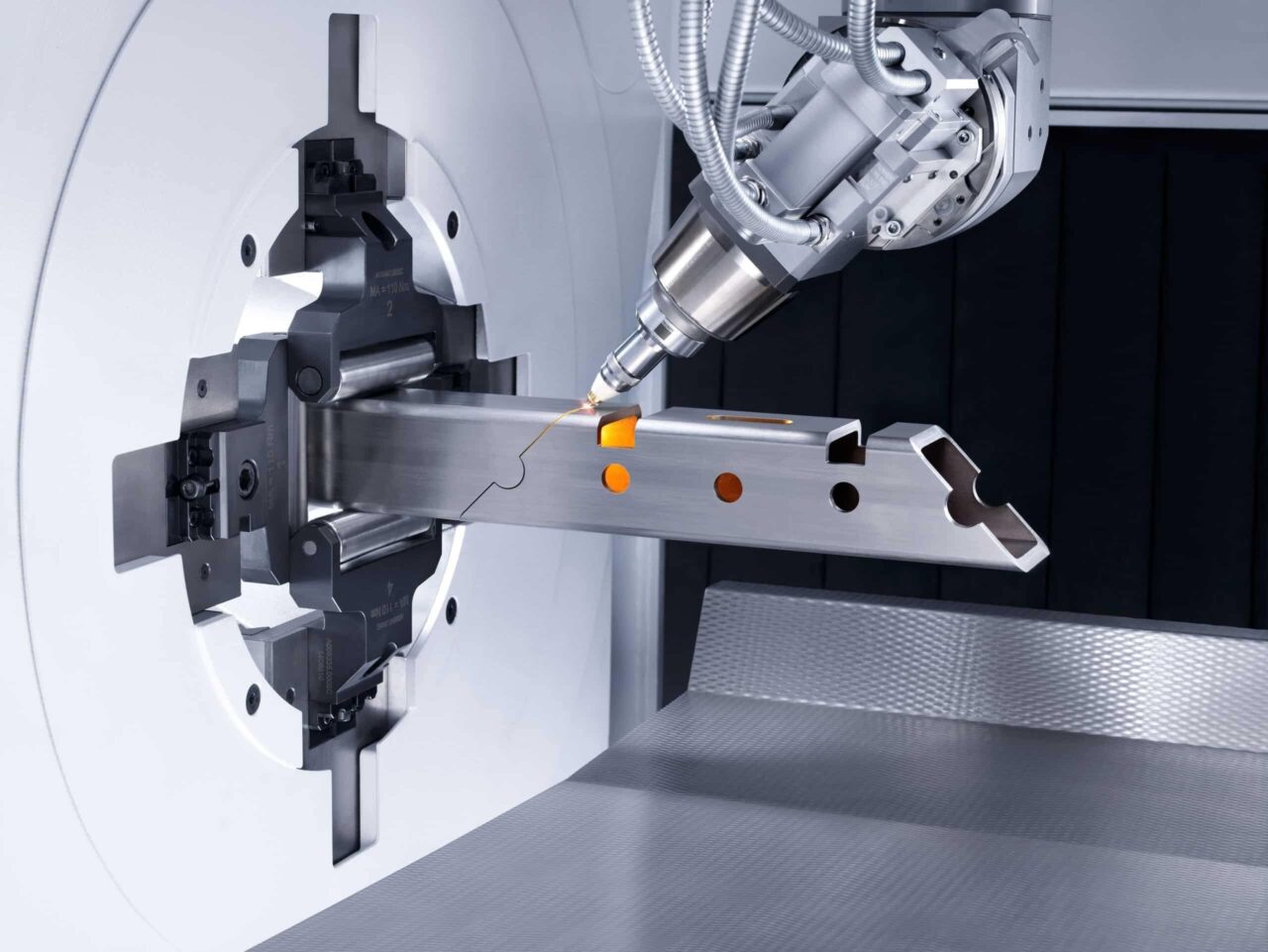

Efficiency is at the heart of multi-axis tube laser cutting. Our tube laser cutting machines are capable of performing multiple operations in a single setup, including bevel cutting, countersinking and even flow drilling and tapping. This consolidation of processes not only speeds up production but also significantly reduces labour and material handling costs.

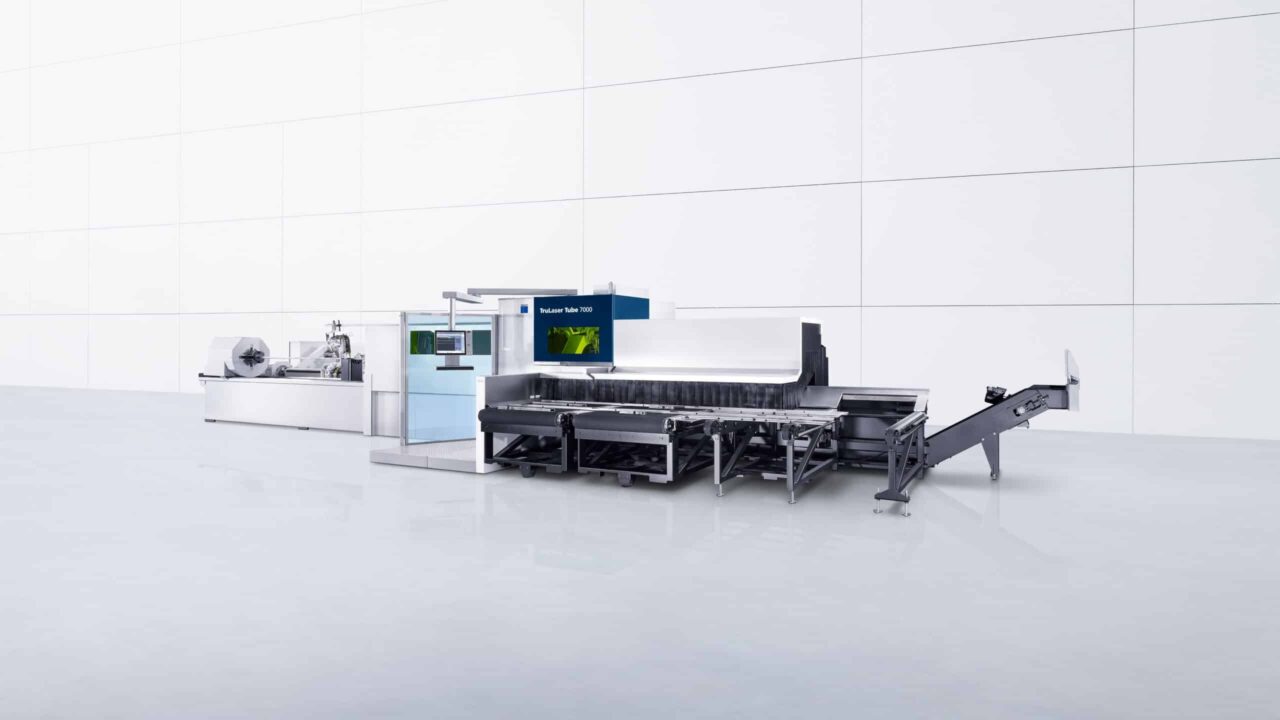

Our tube laser cutting machines, such as the TruLaser Tube 7000 Fibre Machine, provide rapid lead times and competitive pricing. With our Smart Design Production services, we reduce the number of steps in the manufacturing process, we can deliver projects faster and at a lower cost, passing these savings on to our customers.

Superior Accuracy and Quality

Precision is a hallmark of laser cutting, and multi-axis tube lasers take this to the next level. With an accuracy of +/- 0.25mm, these machines ensure that parts are cut to exact specifications, reducing the need for rework and enhancing the quality of the final product.

Our multi-axis tube lasers feature in-process bevel capabilities, producing 45° chamfers on both inner and outer contours. This level of precision eliminates the need for time-consuming weld preparation, ensuring that parts are ready for assembly right off the machine.

Versatility Across Materials and Applications

Multi-axis tube lasers are incredibly versatile, capable of cutting a wide range of materials including mild steel, stainless steel, copper, brass, bronze, and aluminium. This flexibility makes them suitable for various industries, from automotive and aerospace to construction and furniture manufacturing.

At The Laser Cutting Co., our tube laser cutting services can handle sections up to 12000mm in length and materials up to 15mm thick. This capacity allows us to accommodate a diverse array of projects, from small, intricate components to large, structural sections.

Improved Downstream Productivity

By integrating multiple cutting and profiling operations into a single machine, tube laser cutting services streamline the manufacturing process. This integration not only reduces the number of steps but also minimises the risk of errors and inconsistencies, leading to improved downstream productivity.

Our customers benefit from reduced assembly times and lower production costs. With the ability to produce complex parts with fewer joints and welds, tube laser cutting enhances the structural integrity and aesthetic appeal of the final product.

Cutting-Edge Technology and Innovation

At The Laser Cutting Co., we pride ourselves on our commitment to continuous improvement and innovation. Our investment in multi-axis tube laser cutting machines, such as the TruLaser Tube 7000 Fibre Machine, exemplifies this dedication. Featuring advanced technologies like Bevel Cut, RapidCut, and Seamline Tube Detection, our machines offer unparalleled performance and reliability.

These technological advancements not only enhance our capabilities but also provide our customers with a competitive edge. By leveraging the latest in tube laser cutting technology, we ensure that our clients receive the highest quality parts, delivered on time and within budget.

Trust The Laser Cutting Co. for Professional Multi-Axis Tube Laser Cutting Solutions

The benefits of multi-axis tube lasers are clear: enhanced design possibilities, increased efficiency, superior accuracy, versatility, improved downstream productivity and cutting-edge technology. At The Laser Cutting Co., we are proud to offer these advanced capabilities to our customers, ensuring that their projects are completed with the utmost precision and efficiency.

Whether you are looking to streamline your manufacturing process, reduce costs, or explore new design possibilities, multi-axis tube lasers provide the ideal solution.

Contact us today to learn more about how our state-of-the-art tube laser cutting services can benefit your next project.