With over four decades of hands-on expertise and experience, we here at The Laser Cutting Co. understand that selecting the right metal cutting technology—be it plasma or laser cutting—can significantly impact your project’s efficiency, cost, and quality. Each method has its distinct advantages and is suited to different applications.

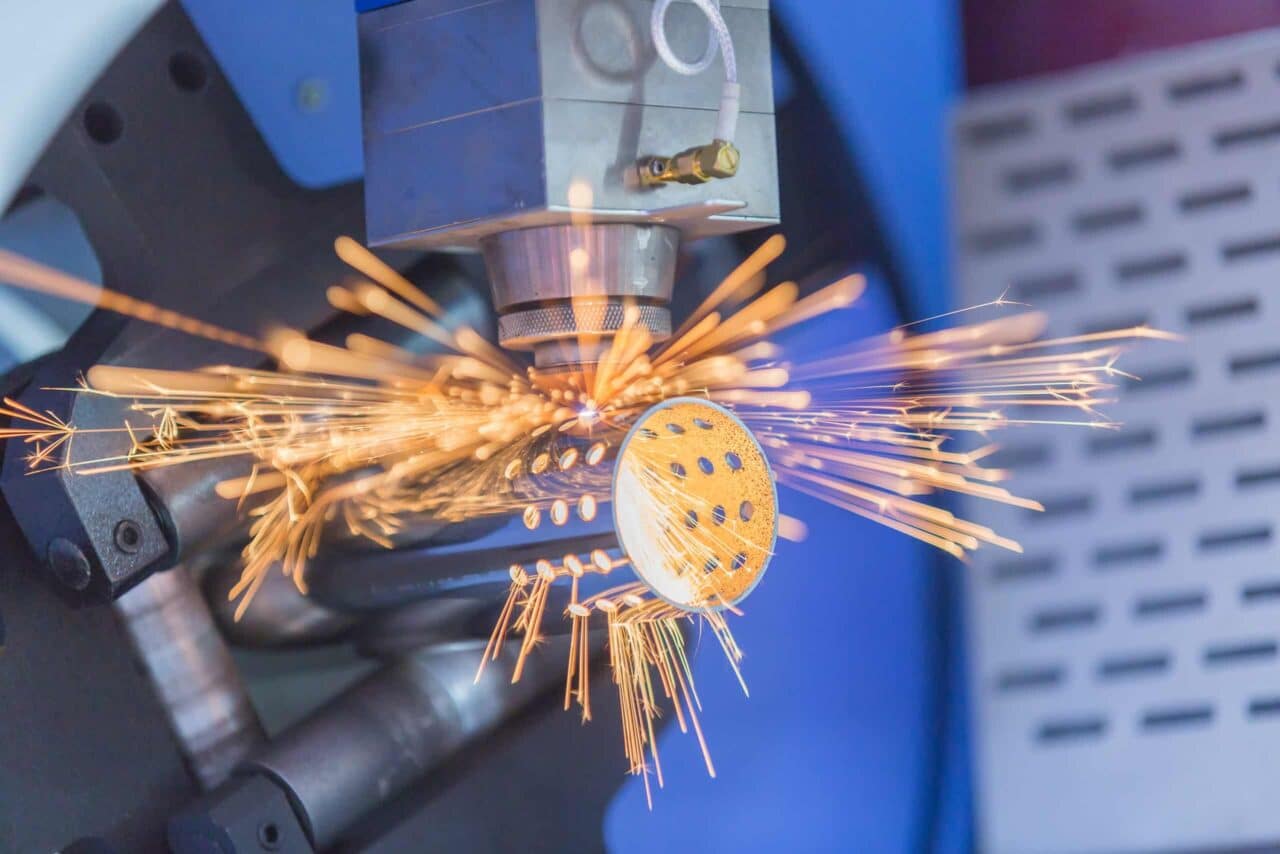

Plasma Cutting: Power and Precision for Thick Metals

Plasma cutting is a high-definition technology that employs a jet of ionised gas at temperatures exceeding 20,000 °C to melt and remove material. This method is ideal for profiling stainless steel, carbon steel, mild steel, and aluminium, handling materials up to 12m x 5m and up to 40mm thick.

Advantages of Plasma Cutting

Versatility in Material

Unlike flame cutting, plasma cutting can process a wider range of materials, including stainless steel and aluminium. This versatility makes it suitable for various projects.

Edge Quality and Accuracy

Plasma cutting delivers high-accuracy edge squareness with a top face accuracy tolerance of +/- 1.0mm and an edge squareness of fewer than 3 degrees, resulting in cleaner cuts and reducing the need for additional finishing.

Speed and Cost Efficiency

Plasma cutting can be faster and more cost-effective than flame cutting for certain thicknesses, providing rapid turnaround times on both complex and high-volume orders. Our 24-hour cutting operations ensure we meet tight deadlines.

High Capacity and Flexibility

Capable of cutting materials up to 40mm thick, our twin-head plasma cutting machines handle large sheets, making it an excellent choice for heavy-duty applications.

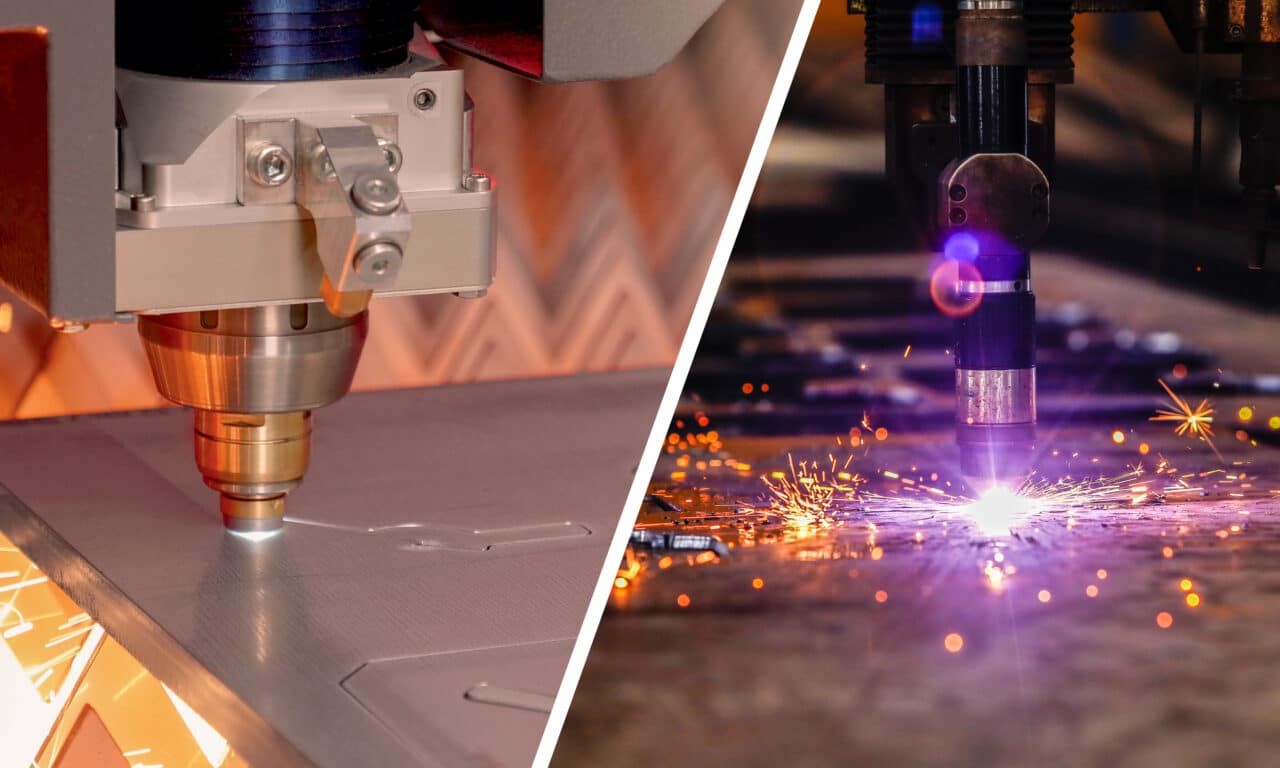

Laser Cutting: Precision and Efficiency for Complex Designs

Laser cutting uses a focused beam of light to cut materials, known for its precision and suitability for intricate cuts and fine contours. Our suite of 10 laser cutting machines operates 24/7, ensuring rapid lead times and high-quality results.

Advantages of Laser Cutting

Unrivalled Precision

Achieving cutting tolerances of +-0.25mm, laser cutting is ideal for projects requiring detailed and intricate designs. The precision allows for tight nesting of parts, optimising material usage and reducing waste.

Versatile Applications

Laser cutting can handle various materials and thicknesses, from sheet metal sizes up to 2000 x 4000mm and thicknesses up to 50mm.

Additional Profiling Services

The laser cutting process can integrate additional services like flowdrill and tapping, 45° bevel edges, and countersinks of any size, eliminating the need for time-consuming weld preparations and enhancing downstream efficiency.

Advanced Technology

Continuous investment in the latest laser cutting technology ensures we provide the highest quality profile cut parts. Automated application of bevels and countersinks during cutting further streamlines production.

Comparing Plasma Cutting Vs Laser Cutting

Material Compatibility

Plasma Cutting

Excels in cutting thicker materials (up to 40mm) and is suitable for a wider range of metals, including carbon steels, stainless steel, and aluminium.

Laser Cutting

Best for thinner materials and projects requiring high precision and intricate cuts, handling materials up to 50mm thick depending on the type.

Cut Quality

Plasma Cutting

Offers a smoother cut edge compared to flame cutting, with good edge squareness.

Laser Cutting

Provides superior precision with a finer edge, ideal for detailed work.

Speed and Efficiency

Plasma Cutting

Generally faster for thicker materials, with high throughput capacity.

Laser Cutting

Offers rapid cutting for thin materials and complex shapes, optimising material usage and reducing overall costs.

Cost

Plasma Cutting

Often more cost-effective for thicker materials and large-volume orders.

Laser Cutting

While potentially more expensive, it delivers high precision and reduces the need for additional processing.

Trust The Laser Cutting Co. for Professional Laser Cutting and Plasma Cutting Services

Both plasma and laser cutting have distinct advantages for different types of projects. Plasma cutting is ideal for thicker materials and projects requiring robust performance across various metals, whereas laser cutting excels in applications demanding high precision and intricate designs, enhancing material efficiency and reducing downstream work.

Choosing the right method depends on your specific requirements, including material type, thickness, desired cut quality, and project complexity. For tailored advice and to explore the best cutting solution for your needs, contact our experienced sales team today.