Laser cutting machines are valuable technology in modern manufacturing and processes, offering streamlined results for a variety of complex, delicate and large-scale projects. Investing in laser-cut parts and materials means ensuring all components are correct for your requirements, avoiding any costly mistakes. However, trying to dictate the right laser for your project can be a confusing process – as experts in laser cutting, we have aimed to eliminate confusion within a condensed guide.

The Difference in Laser Technology

In metal fabrication and laser cutting industries, fibre and CO2 lasers are the most widely used and popular choice for a variety of applications. Each one is defined by the concentration of a high-energy laser beam, its directional power and wavelengths that cut through certain materials.

The main difference between fibre and CO2 lasers is the source in which the laser beam is created. One is generated from a solid-state medium, while the other utilises gas; each one suitable for cutting different materials of a high standard.

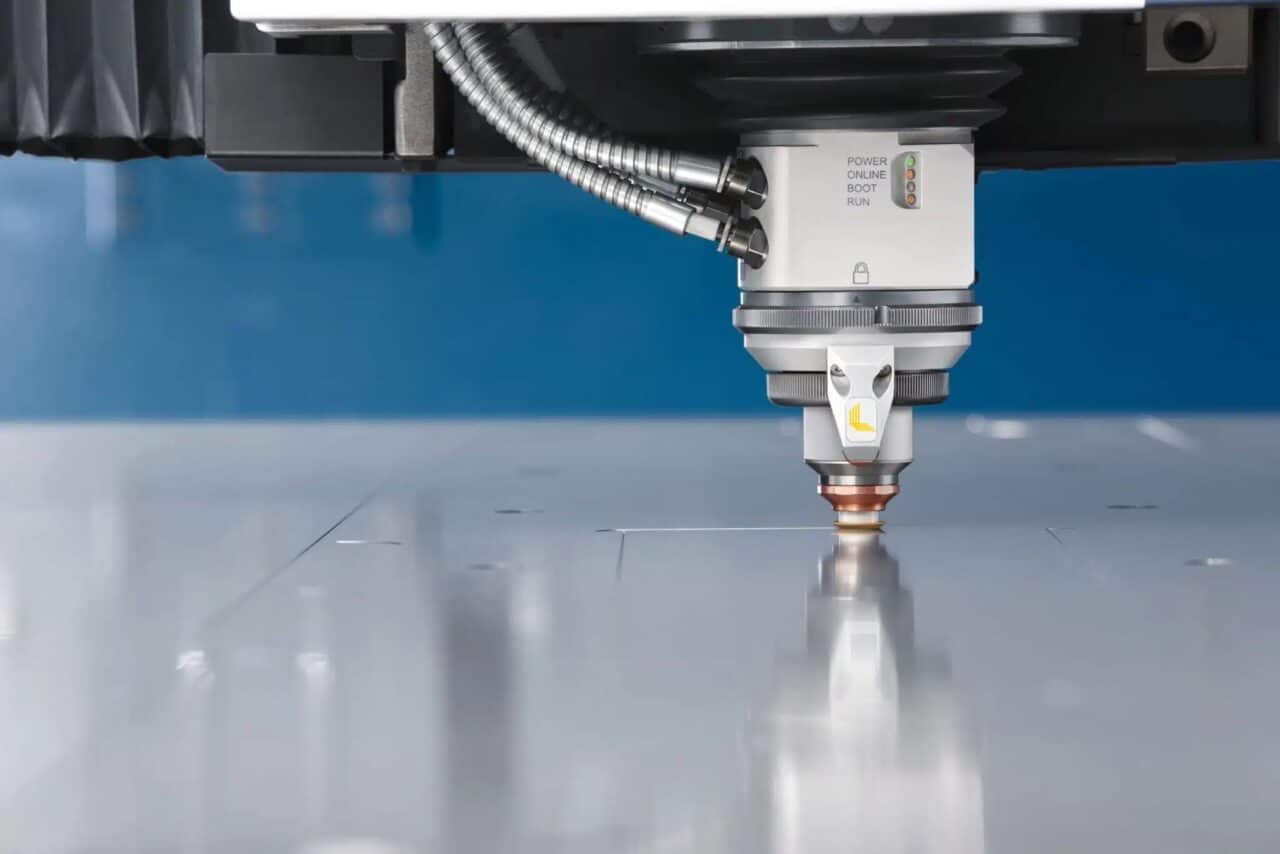

Fibre Lasers

Fibre laser cutting machines work by pumping light through a thin fibre optic cable that is “doped” with elements such as ytterbium or erbium, allowing the laser to perform over various wavelengths. This process absorbs the light and is emitted as a highly focused laser beam to guarantee accuracy with minimal diffraction.

Fibre lasers are known for their excellent power output, rapidly cutting materials within small tolerances and across demanding operations. Due to this reason, they are arguably the most popular choice in metal profiling due to their versatile processes and ability to handle reflective metals such as aluminium, copper and bronze incredibly well.

What Can Fibre Laser Cut?

Fibre lasers provide dynamic options when it comes to laser cutting, the most applicable materials include:

Industry Applications

Fibre lasers are utilised across a wide spectrum of industries due to their reliable performance and high standard of quality, as fibre lasers continue to evolve, further innovation will consistently revolutionise the industry.

- Aerospace

- Automotive

- Construction

- Medical

- Electronics

- General Fabrication

The Benefits of Fibre Lasers

There are several benefits of fibre laser cutting, including:

High precision

Fibre lasers can cut a variety of materials across a range of thicknesses with minimal kerf and flexible control over the entire process, even during remote processing.

Speed

Due to the absorption properties of the fibre optic and the concentration of light in a small space, production times can rapidly increase without degrading quality.

Reliable

Fibre lasers can handle large volumes of production while retaining high-quality standards. Due to the elimination of delicate optical components and mirrors, which occasionally misalign and require replacements, fibre lasers have very low maintenance requirements.

Energy Efficient

Fibre lasers consume less power than CO2 lasers, which makes them excellent at providing energy-efficient processes. This is ideal for businesses looking for ways to manage expenses over long projects.

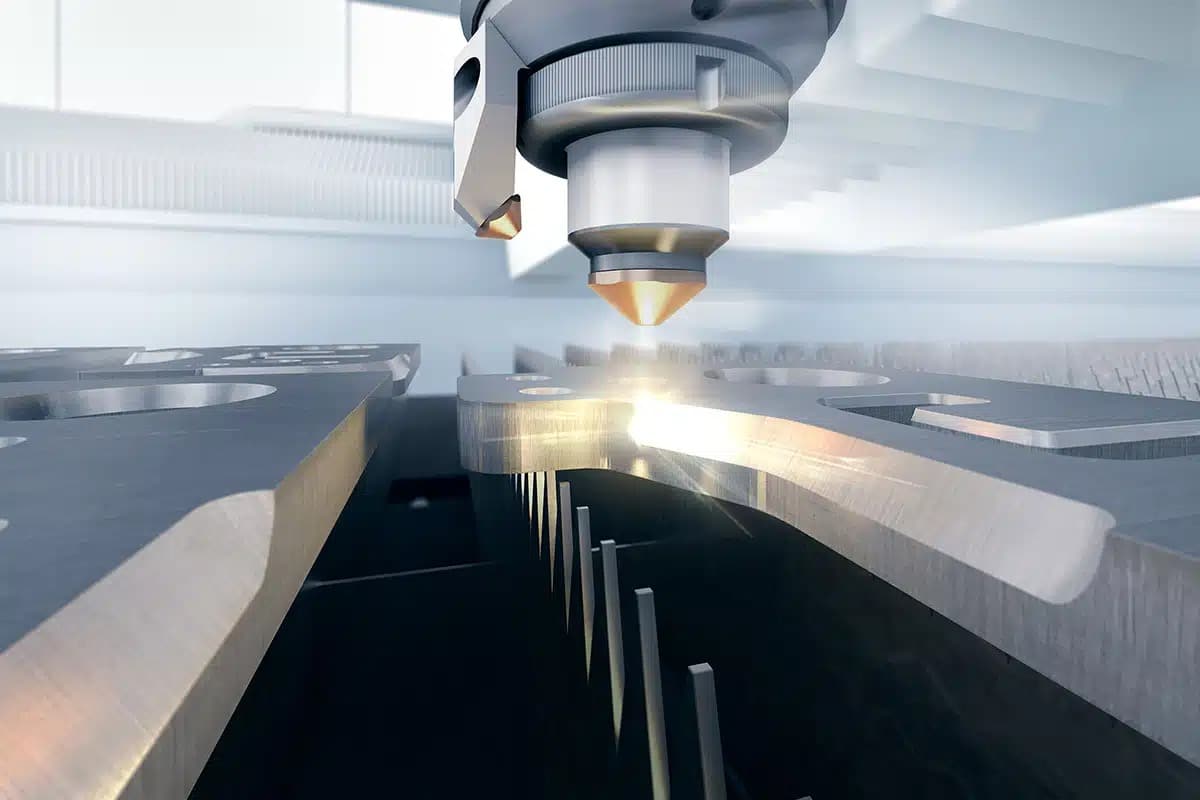

CO2 Lasers

CO2 lasers offer versatile applications, providing highly accurate cutting across various materials, notably those which are non-metallic. The system works by energising molecules in a mixture of gases, including carbon dioxide, nitrogen and helium with an electric current. Within a glass tube, the molecules are stimulated to emit light which bounces off mirrors at each end. As the light reflects back and forth, the intensity of the beam grows, and it begins to generate heat. This heat and light can then be directed into a single point for accurate laser cutting.

What Can CO2 Lasers Cut?

Due to the slightly wider beam of CO2 lasers, they are generally preferable for cutting and engraving non-metallic materials and those with depths above 5mm, these include:

- Wood

- Acrylic

- Glass

- Rubber

- Ceramics

- Textiles

- Metals

Industry Applications

Similarly to fibre lasers, CO2 lasers are applicable across several large industries as reliable laser-cutting machines due to their ease of use.

- Aerospace

- Automotive

- Construction

- Medical

- Textiles

- Woodworking

- Packaging

The Benefits of CO2 Lasers

There are multiple benefits of CO2 Lasers, including:

Safety

CO2 lasers are classified as class 1 lasers, which makes them incredibly safe for use since no radiation can escape. A CO2 laser is even suitable to be used in educational sectors and for personal use.

Precision

When monitored to avoid excessively high temperatures, CO2 lasers provide precise cutting and engraving services.

Versatile

CO2 lasers are capable of cutting a wide spectrum of metallic and non-metallic materials, making it an incredibly versatile application.

Cost Effective

A large reason why CO2 lasers remain so popular is due to how attractive they are cost-wise. CO2 lasers are substantially cheaper than their fibre laser counterparts.

Find the Right Laser for Your Project with The Laser Cutting Co.

Deciding between fibre lasers vs. CO2 lasers is prospective to your project requirements, material use and expected outcomes. With over 40 years of experience in metal profiling, fabrication and laser cutting, we are confident in offering you the most optimal laser cutting solution for your needs.

Beginning your project with the correct laser requirements will ensure you’re set up for success and can achieve obtainable outcomes. If you’re looking for further guidance, our expert team are here to help – contact us today for an obligation-free quote.