Professional Titanium Cutting Services

Titanium, renowned for its exceptional strength, superior corrosion resistance and relatively light-weight, is expertly handled by our high-powered fibre laser cutting services. Our state-of-the-art laser cutting machines can effortlessly profile titanium plates up to 6m x 2.5m and up to 10mm thick, ensuring precision and efficiency.

Due to its challenging properties, titanium requires advanced laser technology for optimal results. Our fleet of fibre lasers meets these challenges, providing faster and more cost-effective solutions compared to conventional methods. With continuous operation of our laser machines, we guarantee impressively short lead times for all titanium parts.

Whether utilising our extensive material stock or processing free-issue materials, we deliver industry-leading profiling services across all grades of titanium. Widely used in aerospace, our titanium cutting expertise also spans industries such as jewellery manufacturing, design, engineering, and architecture. Our CNC-driven machines can directly interpret CAD drawings, achieving high-quality cuts with remarkable accuracy.

Why Trust The Laser Cutting Co. for Titanium Cutting?

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Putting Quality and Efficiency First with Titanium Laser Cutting

With over four decades of refined laser cutting expertise, The Laser Cutting Co. proudly stands as one of the UK’s premier metal profiling companies. We specialise in profiling a broad spectrum of materials for a variety of sectors and industries. Our philosophy of continuous reinvestment in cutting-edge profiling technology ensures we consistently surpass our customers’ expectations. Our dedication to quality assurance, extensive cutting and profiling capabilities, wide range of metal sizes and thicknesses, competitive pricing, and round-the-clock production distinguish us from our competitors.

What are the Benefits of Laser Cut Titanium?

Laser cutting has revolutionised the fabrication industry, particularly in its application to titanium. Some benefits of employing laser cutting for titanium materials include:

Precision Cutting

Titanium's excellent thermal conductivity allows for precise cuts with minimal distortion, resulting in high-quality finished products.

No Surface Contact

As a non-contact process, laser cutting minimises the risk of surface damage and contamination, preserving the integrity of the titanium.

Versatility

Our laser cutting technology can handle all grades and thicknesses of titanium, making it suitable for a wide range of applications.

Complex Shapes

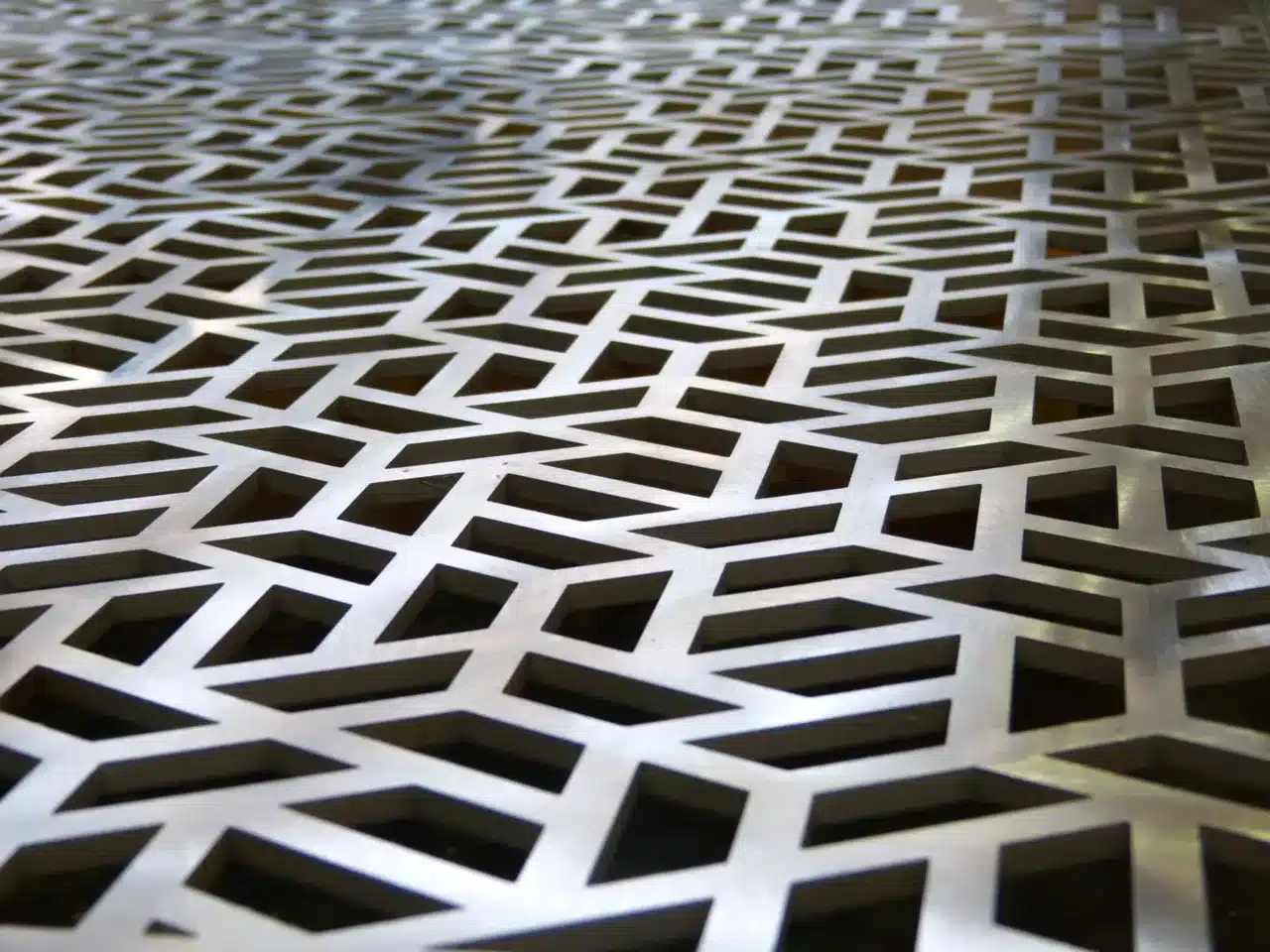

Our CNC-driven machines can create intricate and complex shapes with high precision, essential for custom components and designs.

Clean Cutting Edge

Laser cutting produces smooth, clean edges, reducing the need for secondary finishing processes and streamlining production.

Minimal Distortion

Compared to traditional cutting methods, laser cutting generates minimal heat-affected zones and distortion in titanium, ensuring the structural integrity of the material is maintained.

Titanium Cutting Applications

Here at The Laser Cutting Co., we laser cut titanium for a wide number of clients across various industries. Common applications include:

- Aerospace: Aircraft frames, engine components, various structural parts.

- Art, Creative and Design: Sculptures, decorative elements, bespoke designs.

- Jewellery Manufacturing: High-precision, intricate designs

- Architecture: Cladding, structural components, decorative elements.

- Medical: Surgical instruments, implants, prosthetics.

- Subsea: Underwater structures, components.

- Aerospace: Aircraft frames, engine components, various structural parts.

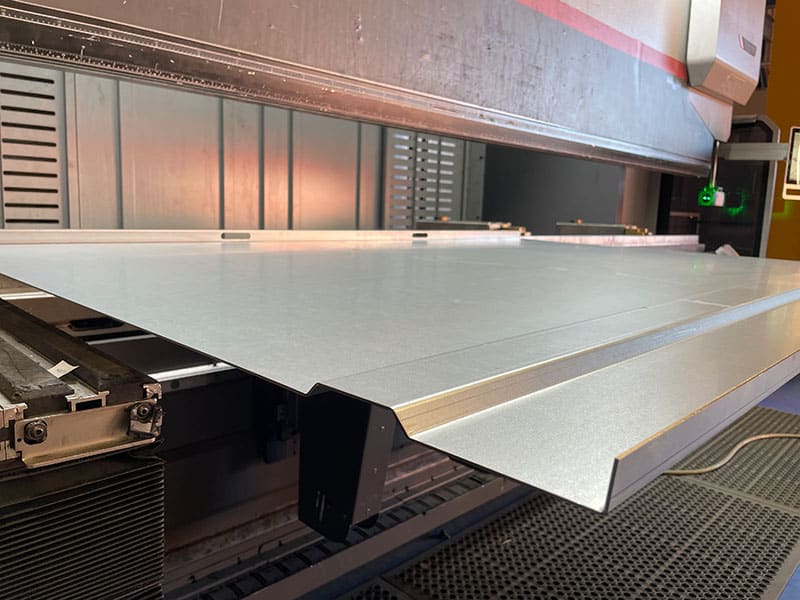

In-House Bending and Pressing

At The Laser Cutting Co., we have enhanced our flatbed cutting capabilities by adding in-house metal bending and pressing services. Our state-of-the-art facility ensures rapid project turnaround and 24-hour continuous production, optimising the assembly phase and upholding the highest quality standards.

Our equipment handles a variety of materials including titanium, mild steel, stainless steel, copper and more. For further details about our metal bending and pressing services, please reach out to our team.

Titanium Cutting Grades and Capabilities

Titanium Laser Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) – Larger sheet sizes can be handled by our waterjet machines.

Maximum Material Thickness

10mm

Minimum Material Thickness

0.50mm

Complex Details

Our CNC laser cutting machines are incredibly accurate and can process the most complex profiles and designs. (Thickness of the titanium sheet may impact certain details).

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

We can achieve a consistently high-quality cut edge on Titanium up to 8mm thick. More information on cut edge quality can be found by speaking with our sales team.

Grades

We can cut all grades of titanium and titanium alloys.

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

Tube Laser Cutting Services

We specialise in providing precise and high-quality tube laser cutting services for a variety of materials, including titanium. Our advanced multi-axis tube lasers run continuously, ensuring quick turnaround times and competitive pricing. These state-of-the-art lasers feature 3D cutting capabilities, reducing material costs and enhancing downstream productivity.

No matter the complexity of your project, our in-house design team and comprehensive processing services ensure maximum efficiency and top-notch quality. We handle various tube profiles and offer in-process bevel cutting, delivering fully weld-prepped orders tailored to your specifications. For more information about our tube laser cutting services, please contact our team.