Professional Aluminium Cutting Services

Renowned for its lightweight, corrosion resistance, and versatility, aluminium is a key material in numerous industries worldwide. At The Laser Cutting Co., we leverage over four decades of expertise in metal profiling to offer precision laser cutting services tailored to meet the unique needs of our diverse clientele.

Our advanced CNC laser cutting machines operate continuously, handling a wide range of aluminium grades and alloys with ease, accommodating thicknesses up to 50 mm. We maintain a comprehensive inventory of aluminium materials, ensuring rapid procurement and project turnaround times. Should your project require specific materials we don’t stock, we can typically source them within 24 hours.

Utilising a fleet of cutting-edge flatbed laser cutting machines and automated systems, we guarantee a seamless workflow from design to delivery, supported by our Smart Design Production facilities.

Why Trust The Laser Cutting Co. for Stainless Steel Cutting?

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Putting Quality and Efficiency First with Aluminium Laser Cutting

With a commitment to excellence and innovation, The Laser Cutting Co. stands out as a premier provider of aluminium laser cutting services in the UK. Our ethos of continuous self-reinvestment drives us to exceed customer expectations through high-quality assurance, an extensive range of cutting services, and competitive pricing. Our round-the-clock production capabilities and extensive selection of aluminium grades and thicknesses ensure we can meet all your project needs efficiently.

What are the Benefits of Laser Cut Aluminium?

Laser cutting has revolutionised the fabrication industry, especially in processing aluminium. Key benefits include:

Precision and Accuracy

Laser cutting allows for incredibly precise and detailed designs, which is essential for applications where even minor deviations can impact performance or aesthetics. This high level of precision ensures that parts fit together perfectly, reducing the need for additional adjustments or rework.

Versatility

Laser cutting is capable of handling various thicknesses and sizes of aluminium, providing flexibility for a wide range of applications. Whether for intricate architectural designs or robust industrial components, laser cutting can meet diverse requirements, accommodating different project specifications with ease.

Clean and Burr-Free Cuts

Aluminium laser cutting produces smooth edges without imperfections, eliminating the need for additional finishing processes. This ensures a high-quality final product, saving time and resources in post-processing and improving the overall efficiency of the fabrication process.

Corrosion Resistance

Aluminium’s natural resistance to corrosion makes it ideal for outdoor and harsh environments. This property ensures longevity and reliability in applications exposed to weather elements or corrosive substances, reducing maintenance needs and extending the life of the product.

Strength and Durability

Despite being lightweight, aluminium maintains excellent structural integrity under stress and prolonged use. This makes it suitable for a variety of applications where weight and strength are critical factors.

Cost-Effectiveness

Aluminium’s durability and low maintenance requirements result in long-term cost savings. Its ability to withstand environmental stresses without significant wear reduces the frequency of replacements and repairs, providing a more economical solution over time.

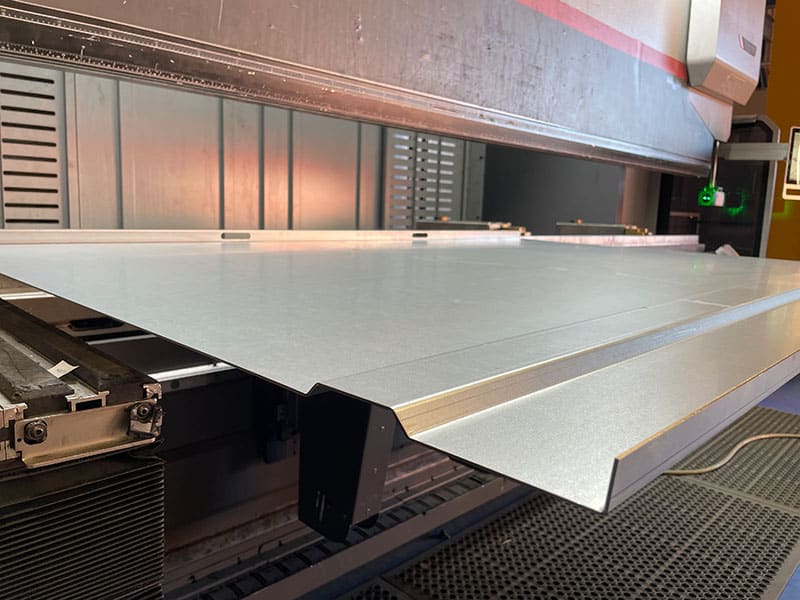

In-House Bending and Pressing

At The Laser Cutting Co., we’ve expanded our services to incorporate metal bending and pressing, all conveniently located within our facility. This setup allows us to expedite project completion through 24/7 production, ensuring both efficiency and top-tier quality in the assembly process.

Our advanced equipment is capable of processing a wide range of materials, such as mild steel, stainless steel, aluminium, copper, and more. For additional information on our metal bending and pressing services, please contact our team.

Aluminium Cutting Applications

Due to its versatility, aluminium can be used for a vast range of applications, including but not limited to:

Ship Building

Necessary for hulls, decks, superstructures, and fittings.

Architectural/Civil Engineering

Utilised for street furniture, structural sections, decorative panels, window frames, and roofing.

Automotive

Essential for vehicle bodies, trailers, truck frames, wheels, and engine components.

Marine Structures

Used for dock components, walkways, offshore platforms, and gangways.

Road Signs

Perfect for traffic signs, direction boards, and road safety barriers.

Hospitality

Commonly used for food industry storage containers, kitchen equipment, and beverage cans.

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

Tube Laser Cutting Services

We offer precise and high-quality tube laser cutting services for various materials, including aluminium. Operating 24/7 for rapid lead times and competitive prices, our state-of-the-art multi-axis tube lasers enable 3D cutting, reducing material costs and enhancing downstream productivity.

No matter the scale or complexity of your project, our in-house design team and comprehensive processing services ensure optimal efficiency and top-tier quality. With capabilities for various tube profiles and in-process bevel cutting, we provide fully weld-prepped orders tailored to your needs. For more information on our tube laser cutting services, please contact our team.

Aluminium Cutting Grades and Capabilities

Aluminium Laser Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) – For larger sheet sizes we recommend waterjet or plasma cutting.

Maximum Material Thickness

40mm

Minimum Material Thickness

0.4mm (Technically we can cut thinner than this but given the malleability of aluminium at such low thickness it can be tricky.)

Complex Details

Our CNC-driven laser-cutting machines are able to process even the most complex and intricate designs.

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

Laser cutting aluminium and aluminium alloys provide a smooth finish quality, although this is sometimes degraded slightly on thicker sheets. As we shroud the laser in Nitrogen gases, it prevents oxidisation ensuring we achieve a clean, blemish-free cut, ready for welding without any extra machining.

We’re able to laser cut aluminium plates and sheets in all grades as well as numerous aluminium alloys. Some of the more common grades we get asked to cut include:

- 1050A

- 1200

- 2014

- 5083

- 5251

- 6061

- 6082

Even if the grade you require is not listed, we could still source and cut it for you. Please contact us with your preferred grade and requirements.