Professional Mild Steel Cutting Services

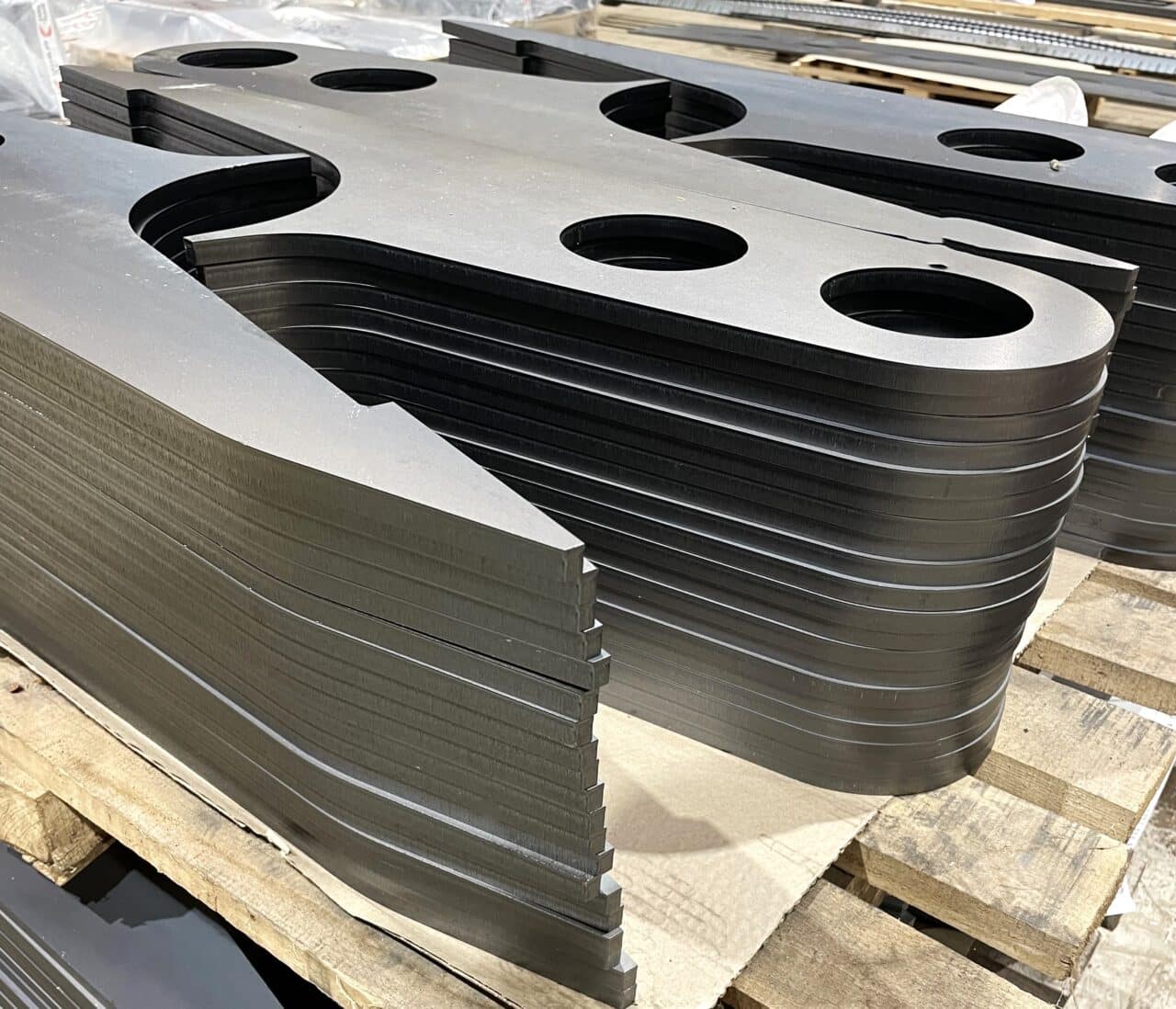

Praised for its affordability, durability and strength, mild steel is utilised across a wide range of industries and sectors globally. Utilising our state-of-the-art laser cutting facilities, we process a diverse range of carbon and mild steels, accommodating thicknesses up to 50mm and sheet sizes reaching 6m x 2.5m. Operational 24/7, our laser cutting machines effortlessly fulfil even the most complex of projects.

Since the installation of our first sub-contract laser cutting machine in 1999, many of our clientele have favoured laser cutting for mild steel due to its superior cut edge quality, rapid lead times, and cost-effectiveness over alternative profiling techniques.

We maintain a stock of popular thicknesses and sheet/plate sizes, with the capability to source materials within 48 hours if not readily available. Additionally, we accommodate laser cutting of your supplied steel materials, with provision for test certificates upon request.

Utilising a fleet of 6 flatbed laser cutting machines and integrated automation systems, our Smart Design Production facilities orchestrate a seamless workflow. This ensures expedited delivery from blueprint to fruition, optimising efficiency and precision.

Why Trust The Laser Cutting Co. for Mild Steel Cutting?

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Putting Quality and Efficiency First with Mild Steel Laser Cutting

Having honed our laser cutting skills and expertise for over forty years, we at The Laser Cutting Co. take immense pride in being one of the UK’s leading metal profiling companies – profiling a diverse array of materials across a range of sectors and industries. With an ethos of continuous reinvestment into the latest profiling facilities, we always endeavour to go above and beyond to exceed our customer’s expectations. Our commitment to quality assurance combined with a diverse cutting and profiling portfolio, wide selection of metals in a variety of sizes and thicknesses, competitive pricing and 24/7 production are what set us apart from the rest of the competition.

What are the Benefits of Laser Cut Mild Steel?

Laser cutting has revolutionised the fabrication industry, especially in its application to mild steel. Here are some benefits of employing laser cutting for stainless steel materials:

Cost-Effectiveness

Mild steel is one of the most affordable materials for laser cutting. Its widespread availability and relatively low cost make it an economical choice for various applications.

Ease of cutting

Mild steel is known for its excellent machinability, making it relatively easy to cut with lasers. This means faster processing times and lower energy consumption compared to cutting harder materials.

High precision

Laser cutting offers exceptional precision, and mild steel is no exception. It allows for intricate designs and tight tolerances, making it suitable for industries where accuracy is crucial, such as automotive, aerospace, and electronics.

Versatility

Mild steel is a versatile material that can be used in a wide range of applications, from structural components to decorative pieces. Laser cutting allows for the creation of complex shapes and designs, expanding the possibilities for product development.

Minimal distortion

Compared to traditional cutting methods like plasma or waterjet cutting, laser cutting generates minimal heat-affected zones and distortion in mild steel. This ensures that the structural integrity of the material is maintained, particularly important for applications where dimensional accuracy is critical.

Smooth edges

Laser cutting produces clean, smooth edges on mild steel without the need for additional finishing processes. This saves time and resources, reducing overall production costs.

In-House Bending and Pressing

We here at The Laser Cutting Co. have expanded our flatbed cutting solutions by offering in-house metal bending and pressing services. Our facility is equipped for fast project turnaround and continuous 24-hour production, optimizing the assembly phase of your project and maintaining the highest quality standards.

We have the capacity to bend and press a wide range of materials, such as mild steel, stainless steel, aluminium, copper, and more. For additional information on our metal bending and pressing services, please contact our team.

Mild Steel Cutting Applications

Mild steel profiling makes up a large percentage of what we cut here at Charles Day, for this reason, we get involved with a whole spectrum of industries. Including, but not limited to:

- Structural Components: beams, columns, structural frames.

- Automotive Parts: chassis, body panels, suspension components etc.

- Pipes and Tubes: used in plumbing, construction, transportation etc.

- Machinery and Equipment: industrial machines and equipment such as agricultural machinery.

- Fasteners and Fixings: nuts, bolts, screws etc.

- Sheet Metal Fabrication: used in various sheet metal fabrication processes to produce panels, containers etc.

- Consumer Goods: used in the manufacturing of household appliances, furniture, kitchen utensils etc.

- Railings and Fencing: often used for railings, fences, gates etc.

- Storage Tanks and Containers: used in the construction of storage tanks, containers, silos etc.

- General Fabrication: used in various general fabrication applications such as welding, cutting, bending, and shaping.

Mild Steel Cutting Grades

We can laser cut steel plates and sheets in numerous grades and alloys. Below is a selection of our most commonly requested grades:

- S275

- S355

- CR4 – Cold Reduced

- EN8

- 400 Wearplate / 400 Brinell

- S690QL High Yield

- Weathering Steel / COR-TEN

- Galvanised

- Tool Steel

- Durbar/Floor Plate

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

Tube Laser Cutting Services

We specialise in delivering precise and high-quality tube laser cutting services across a range of materials, including mild steel. Our advanced multi-axis tube lasers operate around the clock, ensuring rapid turnaround times and competitive pricing. These cutting-edge lasers offer 3D cutting capabilities, minimising material costs and boosting downstream productivity.

Whether your project is large or small, simple or complex, our in-house design team and extensive processing services guarantee maximum efficiency and superior quality. We handle various tube profiles and provide in-process bevel cutting, offering fully weld-prepped orders customised to your requirements. For more details about our tube laser cutting services, please reach out to our team.

Stainless Steel Cutting Capabilities

Maximum Cutting Size

6m x 2.5m (6000mm x 2500mm) – Larger sheet sizes can be handled by our waterjet, flame and plasma machines.

Maximum Material Thickness

50mm

Minimum Material Thickness

0.25mm (Depending on material)

Complex Details

Our CNC laser machines are incredibly accurate and can easily process the most complex and intricate profiles (Thickness of steel may impact certain details).

Cutting Tolerances

View our laser cutting tolerances here.

Cutting Edge Quality

We can achieve a good edge quality when we laser cut mild steel up to 20mm thick. (As the thickness increases the striations on the cut-edge become more prominent.)