Deburring Services in Sheffield

Here at The Laser Cutting Co., we provide professional deburring services to enhance the functionality of your workpieces and complement our unrivalled laser cutting facilities. Leading the way in capability investments, our 40 years of direct industry expertise and experience informs all of our practices, and our in-house capabilities ensure greater downstream efficiencies for the benefit of our customers; producing rapid lead times and saving costs in the process.

What is Deburring?

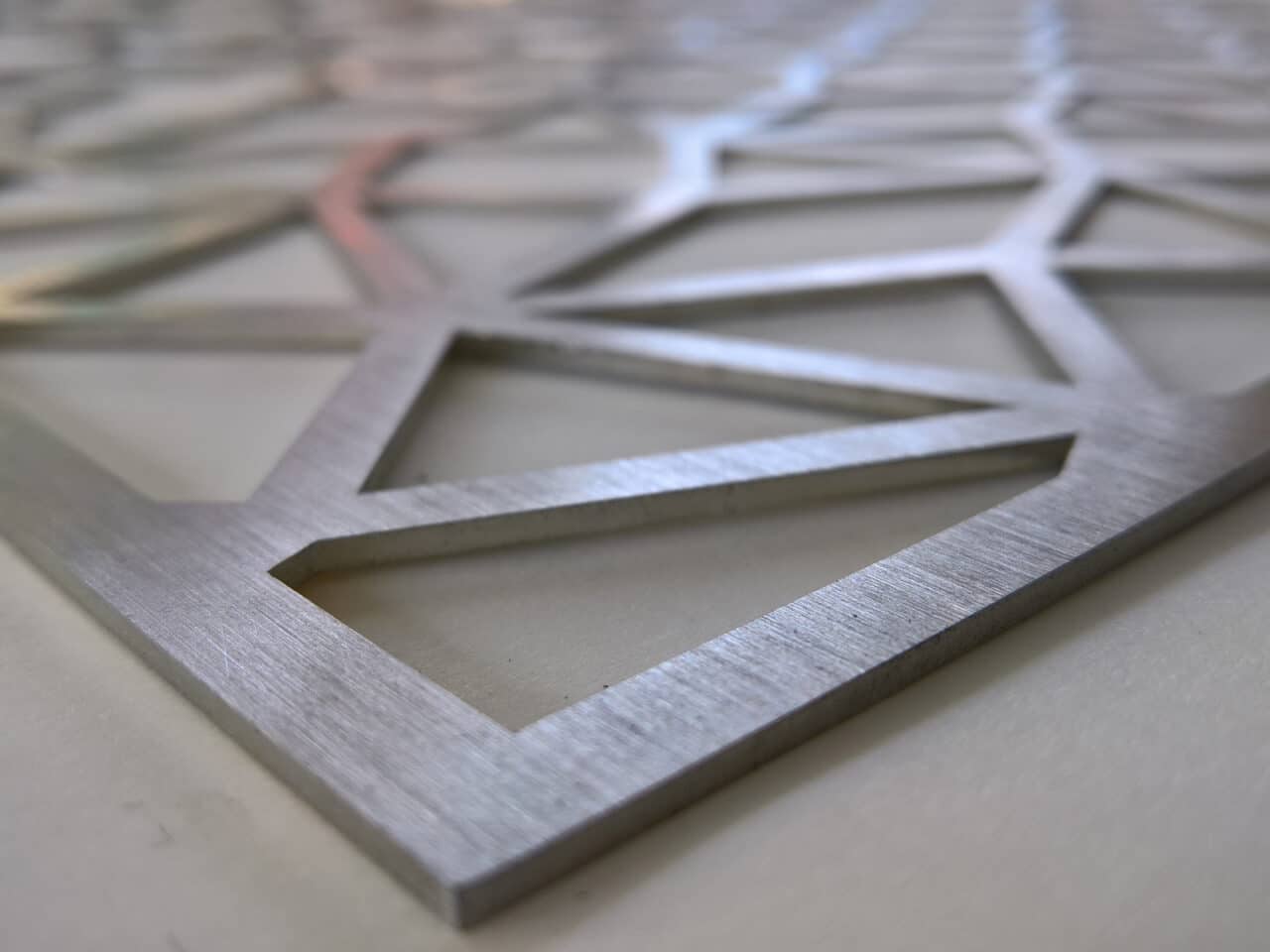

Deburring is the process of removing rough edges, ridges, and excess material left on the edge of a cut part after cutting, grinding and turning processes. Although it is commonly misinterpreted solely as an aesthetic-based service, it is incredibly important for maintaining workpiece durability and reliability long-term and is essential for ensuring the safety and wellbeing of both operators and consumers. By removing burrs from cut parts, you can significantly reduce undesired corrosion and friction, meaning both your machinery and workpieces maintain functionality, as well as adhere to relevant health and safety practices.

What Are The Benefits of Deburring?

- Improved safety for operators and consumers

- Improved durability

- Increased machine longevity

- Reduced assembly times

- Improved workpiece consistency

Our Deburring Services

Dedicated to providing full-service solutions, we offer a range of deburring services to suit varying needs and requirements. With both standard and vibratory deburring available, we are able to remove burrs from your workpieces of all sizes and capacities; our standard burr removal, otherwise known as centrifugal barrel finishing, is suited best to heavy-duty workpieces, whereas our vibrational deburring service is ideal for large or voluminous parts.

Deburring and vibro-deburring FAQ

What is deburring?

Deburring is the process of removing rough edges, ridges, and excess material from the edge of a cut part after cutting, grinding, and turning processes. This process is crucial for maintaining the durability and reliability of workpieces and ensuring the safety of operators and consumers.

Why is deburring important?

Deburring is essential not only for aesthetic purposes but also for functional reasons. It improves the safety of workpieces, reduces the risk of corrosion and friction, and ensures that machinery and parts maintain their functionality while adhering to health and safety standards.

What are the benefits of deburring?

The key benefits include improved safety for operators and consumers, enhanced durability of parts, increased machine longevity, reduced assembly times, and improved consistency in workpieces.

What is vibro-deburring?

Vibro-deburring, or vibratory deburring, is a type of deburring process ideal for large or voluminous parts. It involves using vibrational energy to remove burrs from workpieces.

How does The Laser Cutting Co. perform deburring?

The Laser Cutting Co. offers both standard and vibratory deburring services. Standard burr removal, also known as centrifugal barrel finishing, is best suited for heavy-duty workpieces. In contrast, vibratory deburring is preferred for larger parts.

Can The Laser Cutting Co. handle deburring for any size workpiece?

Yes, we offer deburring services for workpieces of all sizes and capacities, ensuring flexibility and adaptability to various requirements.

Is deburring necessary for all types of metal workpieces?

While not every metal workpiece may require deburring, it is generally recommended for enhancing the quality, safety, and longevity of metal parts, especially those that undergo cutting and shaping processes.

Why Choose The Laser Cutting Co. for Deburring Services?

As leading professionals in outsourced metal profiling and laser cutting services, we understand more than most that every project is different, which is why we consistently re-invest in the latest technology to improve the quality of our services; encompassing any and all profiling requirements that may be requested by our customers.

With 24-hour production, a suite of state-of-the-art laser cutting machines, as well as bending, welding, and sub-assembly capabilities all under one roof, we are able significantly to reduce lead times, producing greater supply-chain efficiencies.

For professional deburring and vibratory deburring services, contact our team of professionals today.