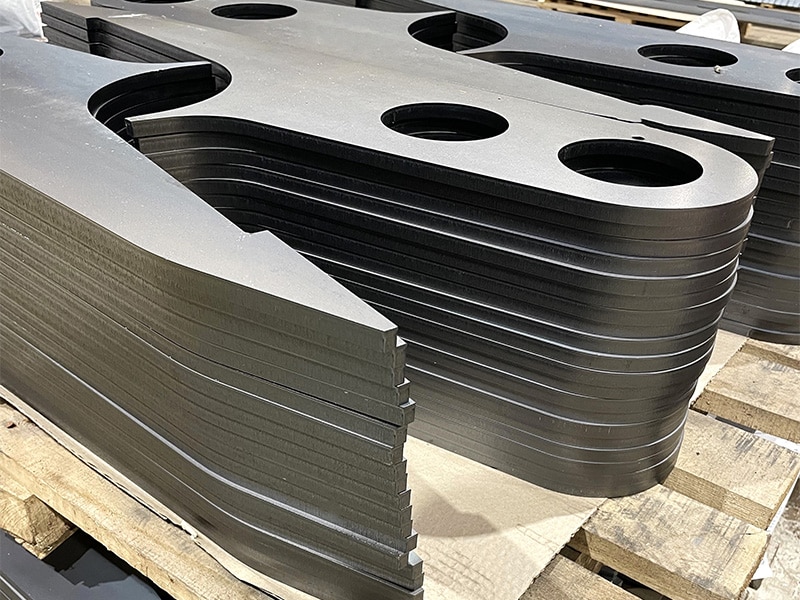

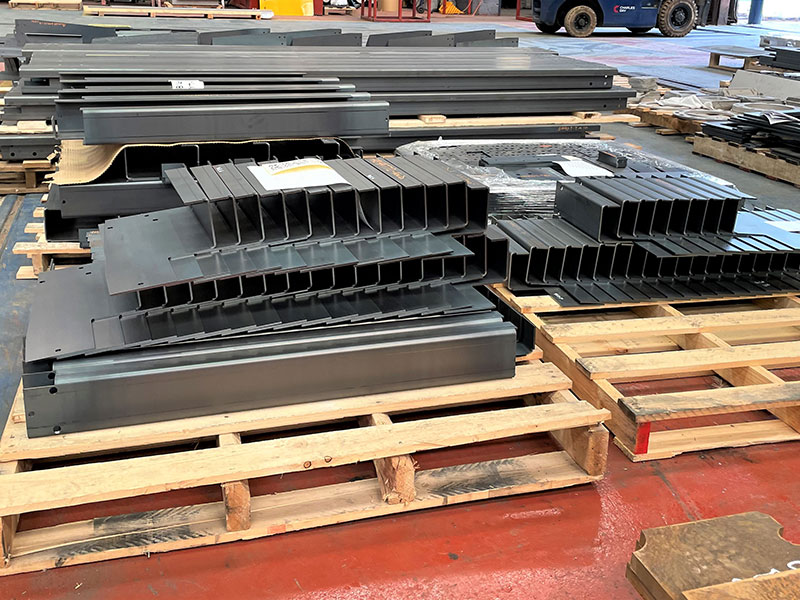

A true one-stop profiling shop, orders are delivered complete and ready for assembly with sheet metal bending services.

Procuring quality and accurate parts has never been easier with a comprehensive range of in-house profiling services.

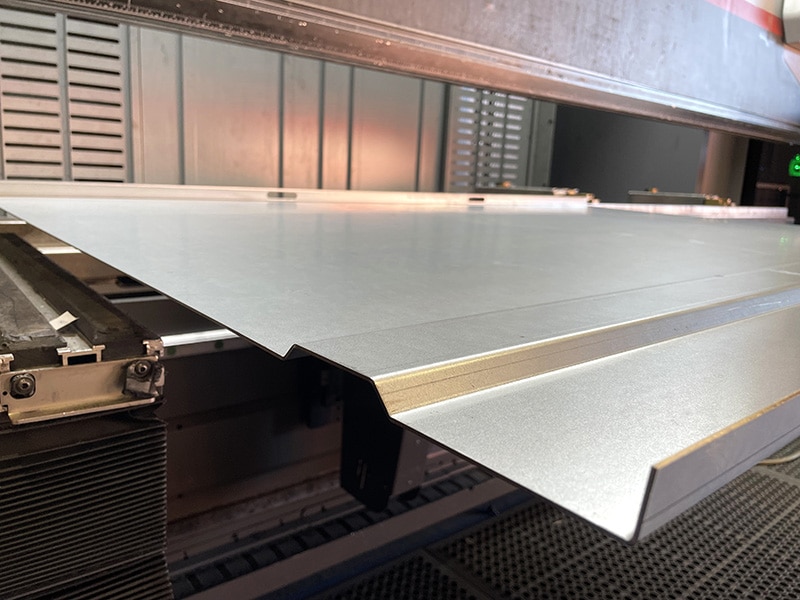

Sheet metal bending, also known as profile bending or press forming, combines operator skill and quality tooling to deliver the consistent quality downstream assembly teams need. At The Laser Cutting Co., ergonomic and efficient machines allow operators to achieve superior quality for customers.

Operating 3 press brake machines to meet a range of project and material requirements. Sheet metal forming capabilities extend to 3100mm width with up to 150-tonne force. TLCC’s suite of CNC brake press machines are capable of both high volume and high complexity profiling.

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Capabilities

Our presses have ability to bend parts up to 4250mm wide.

Our new Trumpf TruBend 5230 press.

Applying 230 tonnes across a bend width of 4250mm, our flat laser cutting and folding services remain at the forefront of the industry’s latest technology.

- Tonnage: 230t

- Bending Length: 4250mm

- Open Height: 1115mm

- Max. working speed: 220mm/s

Extensive tooling

Skilled operators

High volume jobs

Complex projects

Short lead times

Complete Metal Profiling

Sheet metal forming uses a brake press machine to apply bends on a range of metals including mild and stainless steels, and aluminium. Combining the latest metal pressing technologies, including dynamic crowning and laser measuring, delivers exceptional bend accuracy. The Laser Cutting Co. maintain a program of continuous investment to ensure its metal profiling service is second-to-none:- Extensive range of quality tools

- Highly skilled operators

- Laser angle measuring

- Die and panel forming capabilities.

Benefits of Press Braking

One of the key benefits of sheet metal bending is the reduction, or eradication in many cases, of joining processes such as welding. As a result, bending delivers greater part strength and simplified assembly.

- Outsource to avoid machinery investment

- Tooling is expensive to maintain

- Low to medium volume projects don’t justify stamping tools

- Talented brake press operators can be hard to find

- Enormous profiling flexibility.

Our Investment, Your Benefit

We invest in the latest metal profiling technology, so you don’t have to. From drawing to delivery, TLCC customers can outsource as much, or as little profiling as required.

Take advantage of TLCC’s aggregated buying prices when outsourcing metal profiling requirements. Discover even greater efficiencies with Smart Design Production, designing for reduced downstream processes and simplified assembly.

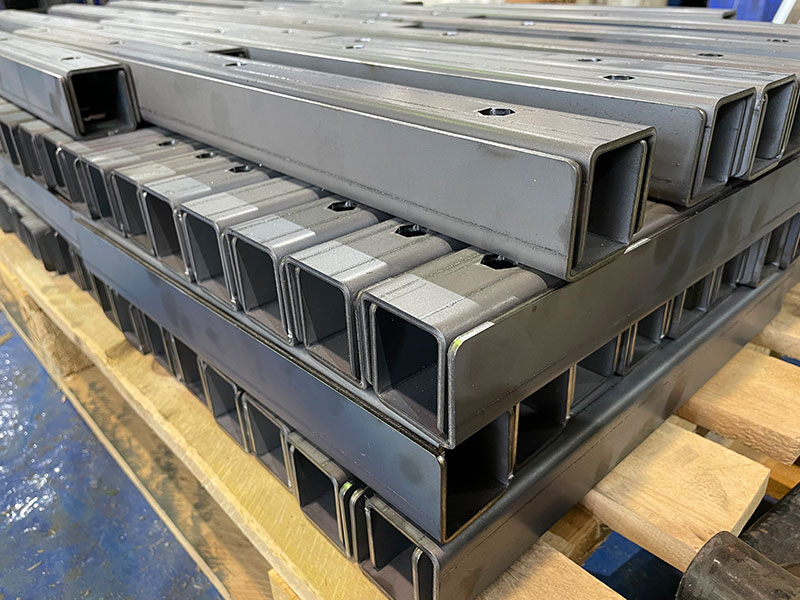

Additional profiling technologies from The Laser Cutting Co. include sheet metal, open section, and tube cutting, 45° bevel and countersinks, flow drill and tapping. Cutting technologies include fibre laser, traditional CO2 lasers, waterjet cutting, plasma and flame cutting.

Sheet Metal Bending FAQ's

What is sheet metal bending, and how does it differ from other metal forming processes?

Open section cutting refers to the process of cutting or dividing a section of a larger object that has an open or hollow shape. It typically involves cutting through the walls or edges of the open section to create separate pieces or components.

For more information regarding our Open Section Cutting services, contact The Laser Cutting Co. today.

What materials can be used for sheet metal bending?

Sheet metal bending can be used for a range of materials, including mild steel, stainless steel, and aluminum.

For more information and guidance, contact the team at The Laser Cutting Co. today.

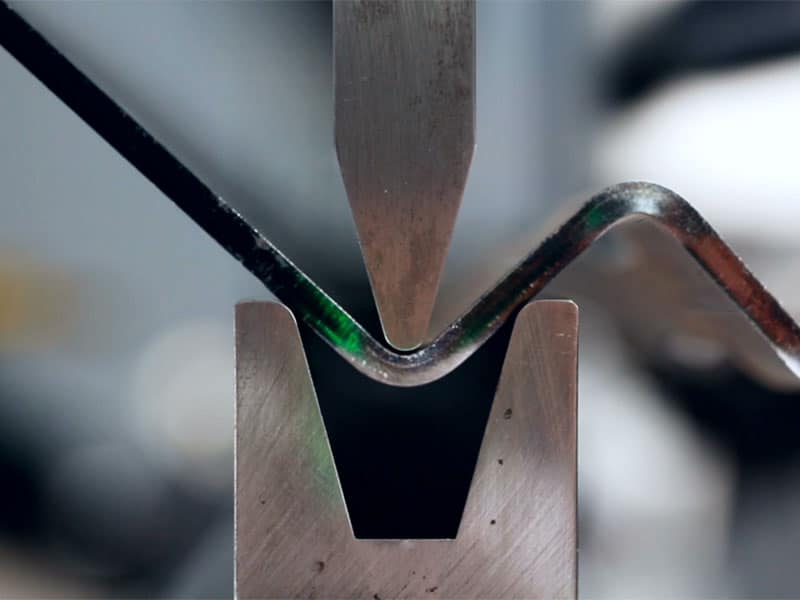

What is a press brake?

A press brake is a machine tool used for bending sheet metal. It consists of a flat surface (bed) and a vertically moving upper tool (punch). The sheet metal is placed between the bed and the punch, and bending occurs when the punch descends and applies force to the metal.

What factors affect the bend radius in sheet metal bending?

The bend radius is influenced by several factors, including the thickness of the metal, the material’s ductility, the angle of the bend, and the tooling used in the process

What is the difference between air bending and bottoming in sheet metal bending?

Air bending is a method where the sheet metal is bent over a specified die, leaving an open space between the punch and the die. Bottoming, on the other hand, involves bringing the punch into direct contact with the die, resulting in a tighter bend.

What is the role of a die in sheet metal bending?

A die is a tool used in sheet metal bending that determines the shape and size of the bend. It works in conjunction with the punch to deform the metal and create the desired bend.

What are the common types of bends in sheet metal?

Common types of bends include V-bends, U-bends, and channel bends. The choice of bend type depends on the application and design requirements

How can I calculate the bend allowance?

The bend allowance is calculated based on factors such as material thickness, bend radius, and the angle of the bend. There are various formulas and software tools available to help calculate the bend allowance accurately.

What are the common challenges in sheet metal bending?

Challenges may include spring back (the tendency of the metal to return to its original shape), cracking, and variations in bend angle. Proper tooling, material selection, and process control can help address these challenges.

Can complex shapes be achieved through sheet metal bending?

Yes, complex shapes can be achieved through a series of bends and using advanced tooling techniques. However, it may require careful planning and expertise in sheet metal forming.

The Laser Cutting Co.’s Quality Promise

The highest possible quality standards with the after sales support to match

Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles

Certified to BS EN ISO 9001:2015 for all profiling requirements

Quality Assurance