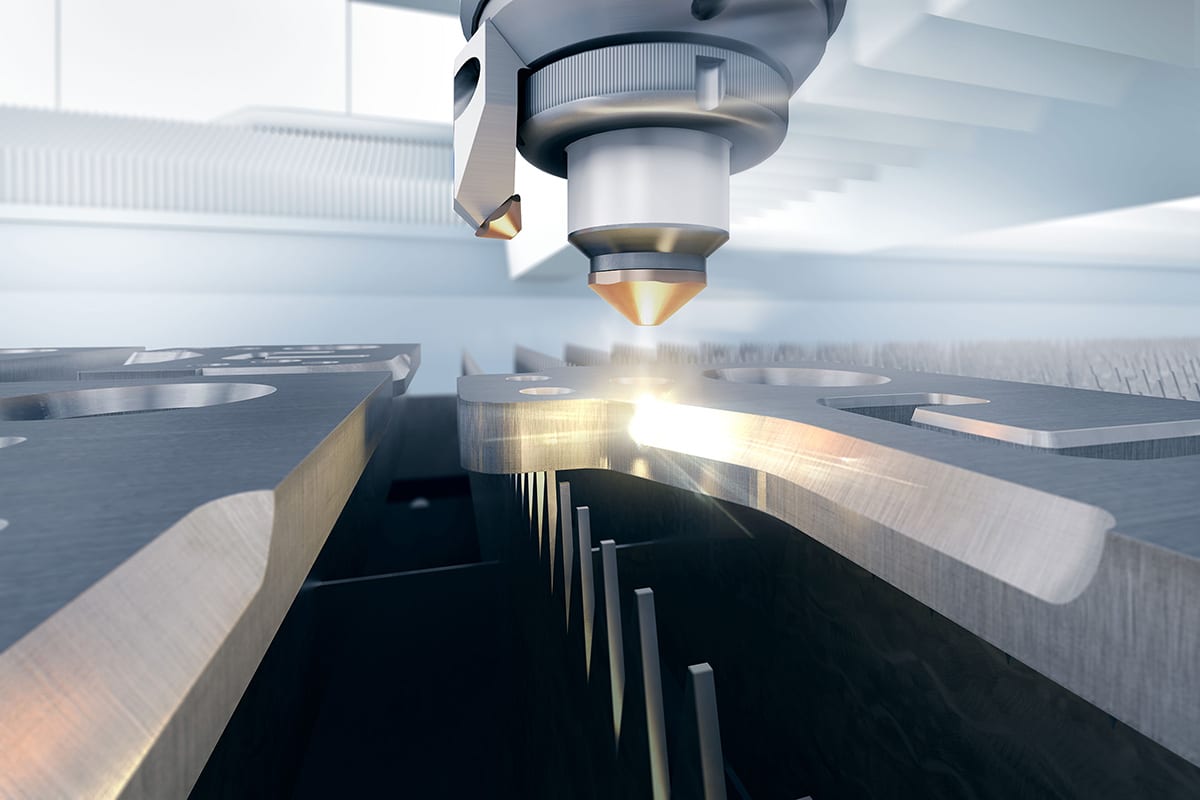

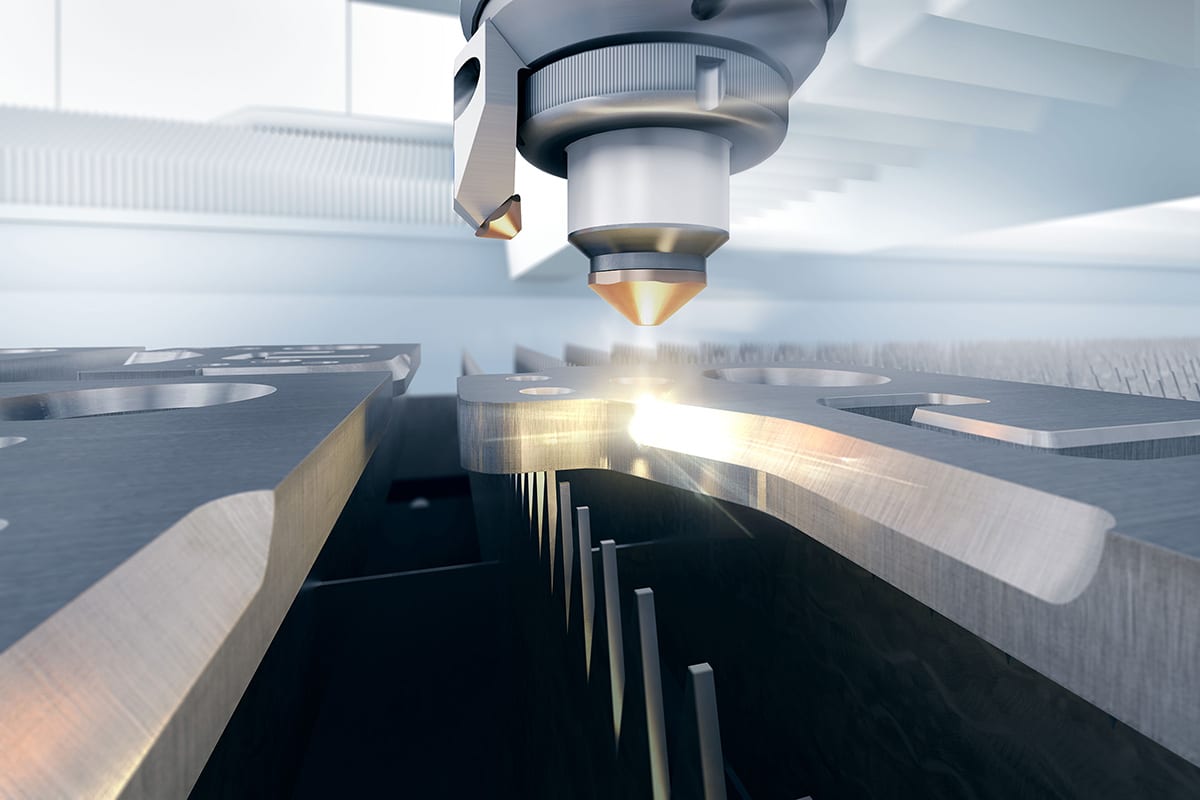

NEW to the world of metal profiling. Automated weld seam preparation with laser cutting, bevel edges up to 45°, and countersinking, all in one.

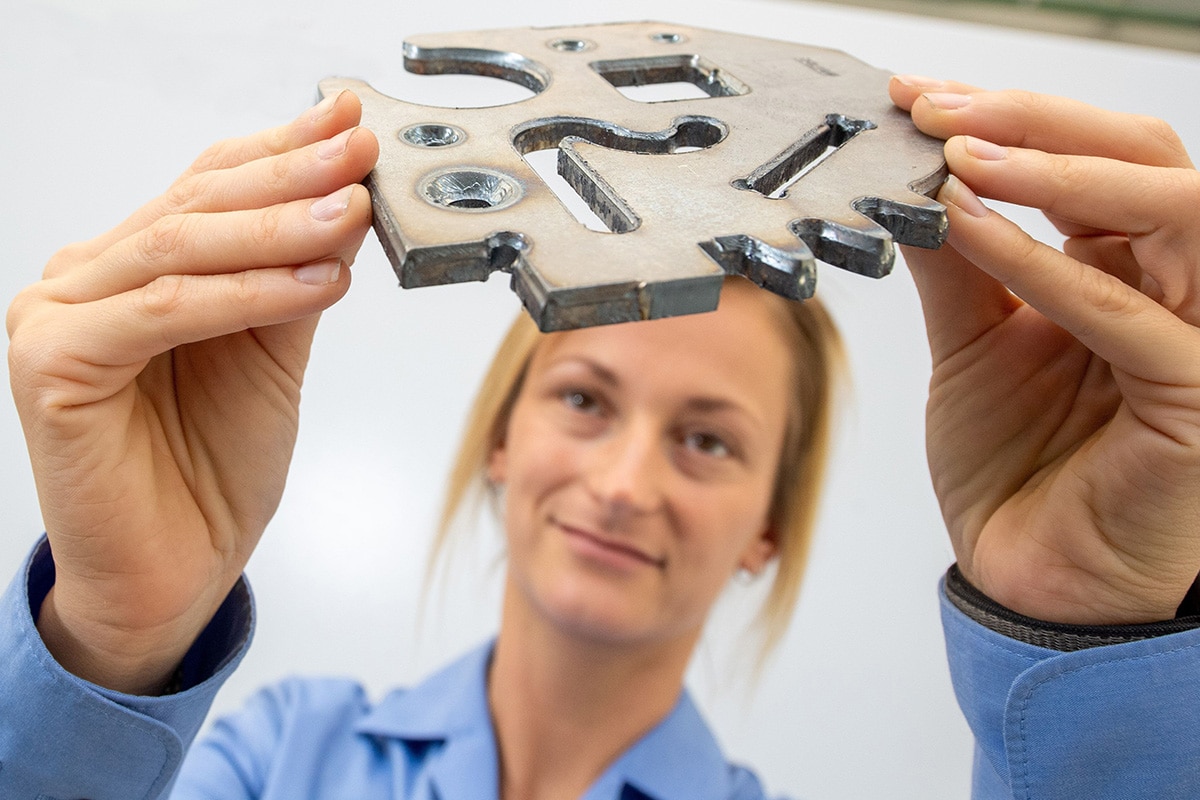

Eliminate the need for time-consuming weld preparation with this industry-first laser cutting service. Automatically cut 45° bevels and countersinks of any size, on both outer and inner contours. The most awkward edges to prepare for welding, inner contours are added during laser cutting for maximum efficiency.

Manual processes will always have an associated margin for error. Avoid the cost and disruption of inaccuracy with a fully automated laser bevel cutting and countersink process. Ideal for both small and large volume profiling jobs, the latest service from TLCC means you can remove manual weld seam preparation from your workflows, for good.

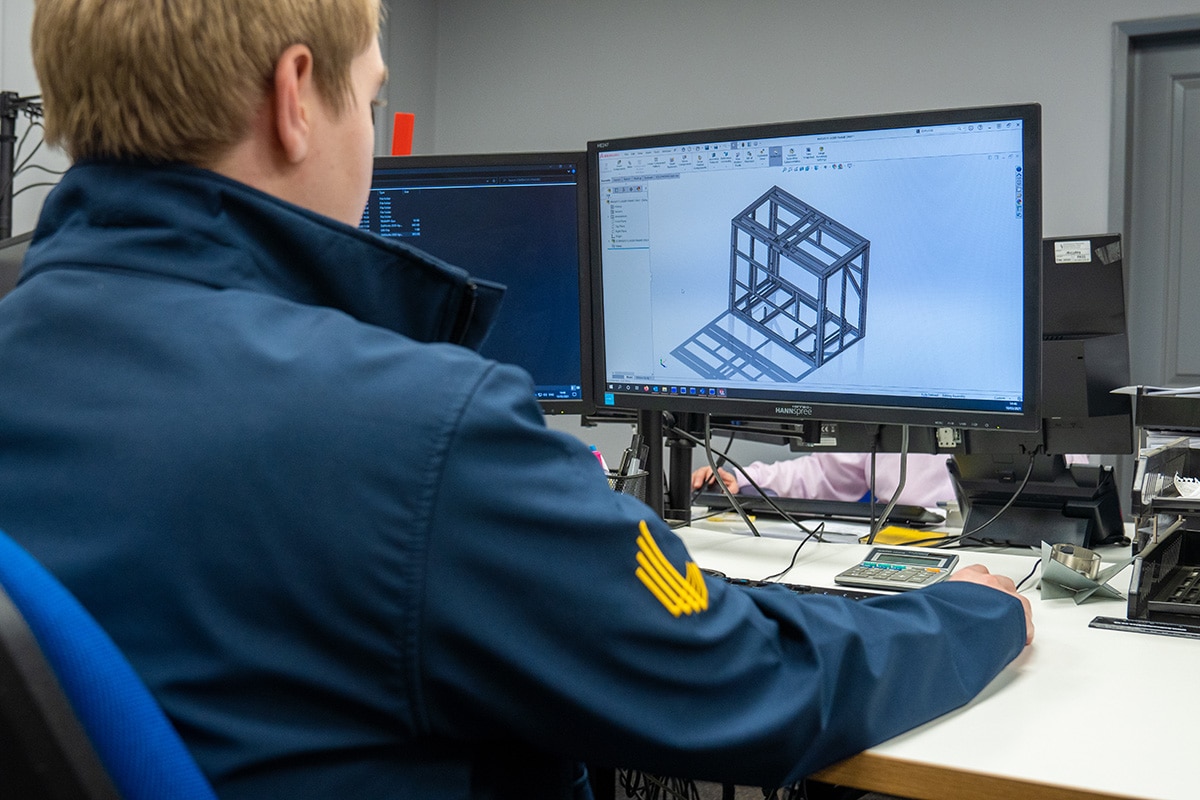

TLCC offer an all-in-one laser cutting service, from design to delivery. Benefit from our aggregated buying prices and take full advantage of our in-house design services. We can help you make significant cost savings in fabrication time with innovative part design, including part folds and self-jigs to +-0.25mm.

Efficiency

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

All-in-one metal profiling

Maximum efficiency

Zero margin for error

Industry leading capacity for high volume projects

Rapid Metal Profiling

Automated laser cut weld preparation is here. Gone are the days of preparing seams by hand or an additional process step on a milling machine. Now, sheet metal can arrive to you cut and weld prepped with unrivalled accuracy.

Push the limits of contouring with laser bevel cutting. Design is unrestricted by time and skill resources, with the ability to produce bevelled edges of various angles up to 45° and countersinks of any size, including screw connections.

Countersink and laser bevel cutting is available for a range of sheet metal sizes and thicknesses up to 30mm. Component quality increases through automation where the possibility of human error is no longer a risk.

Sheet Metal Laser Cutting Thicknesses

Material Thickness (mm)

Your One-Stop Profiling Shop

We invest in the latest metal profiling technology, so you don’t have to. From drawing to delivery, TLCC have a range of services to suit every project. Not only do we offer the latest laser bevel cutting and countersink technology, but we also have an impressive range of cutting technologies including fibre lasers, traditional CO2 lasers, waterjet cutting, and flame cutting.

TLCC customers benefit from aggregated buying costs and efficiency savings from outsourced laser cutting. Take this a step further with our Smart Design Production service. Drawing on the full range of our metal profiling capabilities, TLCC deliver advanced efficiency through design.

Bevel and Countersink FAQ's

What is a bevel edge in metal profiling, and why is it important?

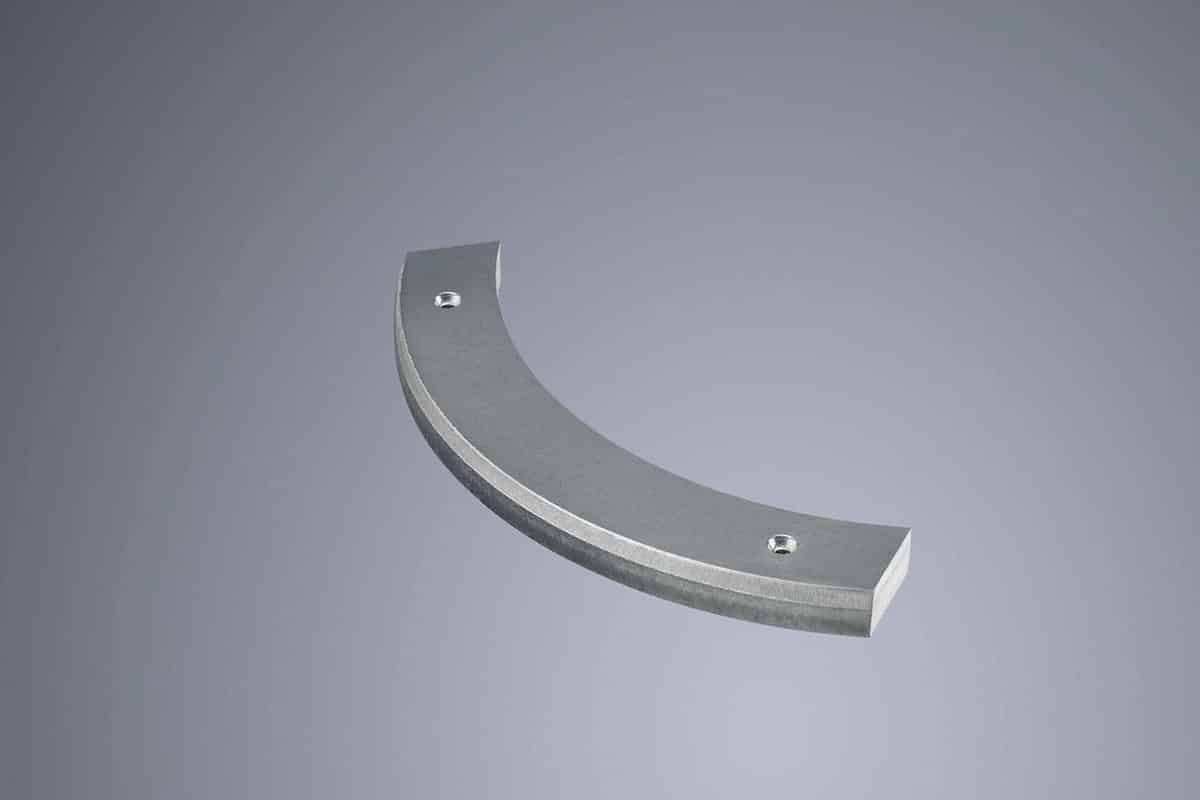

A bevel edge is an angled or sloped edge cut into a metal surface. It’s important because it helps to prepare the metal for welding, ensuring a secure and strong joint between two pieces.

What angles of bevel edges can TLCC provide?

The Laser Cutting Co. offers bevel edges of various angles, with the capability to cut bevel edges up to 45 degrees.

For more information regarding our bevel laser cutting, contact TLCC today.

What is bevel and countersink laser cutting?

Bevel and countersink laser cutting is a precision cutting process that involves creating beveled or countersunk edges on materials using a laser. It’s commonly used for chamfering or creating recessed holes in various materials.

Are countersinks essential in metal fabrication?

Countersinks are crucial in metal fabrication as they create conical-shaped recesses in metal surfaces, and are often used to accommodate screws or fasteners.

Can The Laser Cutting Co. provide bevel and countersink services for both the outer and inner contours of metal components?

Yes, TLCC can perform bevel and countersink cutting on both outer and inner contours, making it suitable for a wide range of applications.

For bevel and countersink laser cutting, contact The Laser Cutting Co. today.

What materials can bevel and countersink laser cutting work on?

Bevel and countersink laser cutting can be performed on a wide range of materials, including metals like stainless steel, nickel alloys, aluminum, brass, copper, and much more.

What are the benefits of countersinking in laser cutting?

Countersinking in laser cutting allows for screws, bolts, or fasteners to sit flush with the material’s surface, which improves the aesthetics of the finished product and reduces the risk of snagging or interference.

What are the typical applications for bevel and countersink laser cutting?

Bevel and countersink laser cutting is commonly used in applications such as aerospace, automotive, electronics, and general manufacturing for creating beveled edges on components, countersinking holes for flush fastening, and improving the aesthetics of finished products.

Is post-processing required after bevel and countersink laser cutting?

Depending on the application, some post-processing may be required to remove any sharp edges or burrs left by the laser cutting process. However, the need for post-processing is often minimal compared to traditional cutting methods.

For deburring and vibro-deburring services, please contact TLCC today.

Why choose bevel and countersink laser cutting over traditional methods?

Bevel and countersink laser cutting offers several advantages over traditional methods, including precise and consistent results, minimal material wastage, reduced setup time, and the ability to cut intricate shapes.

How much do bevel and countersink laser cutting services cost?

The pricing of bevel and countersink laser cutting depends upon the scale of the project and chosen material/s. For a bespoke bevel and countersink quote, get in touch with TLCC today.

Quality Assurance

The Laser Cutting Co.’s Quality Promise

The highest possible quality standards with the after sales support to match

Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles

Certified to BS EN ISO 9001:2015 for all profiling requirements