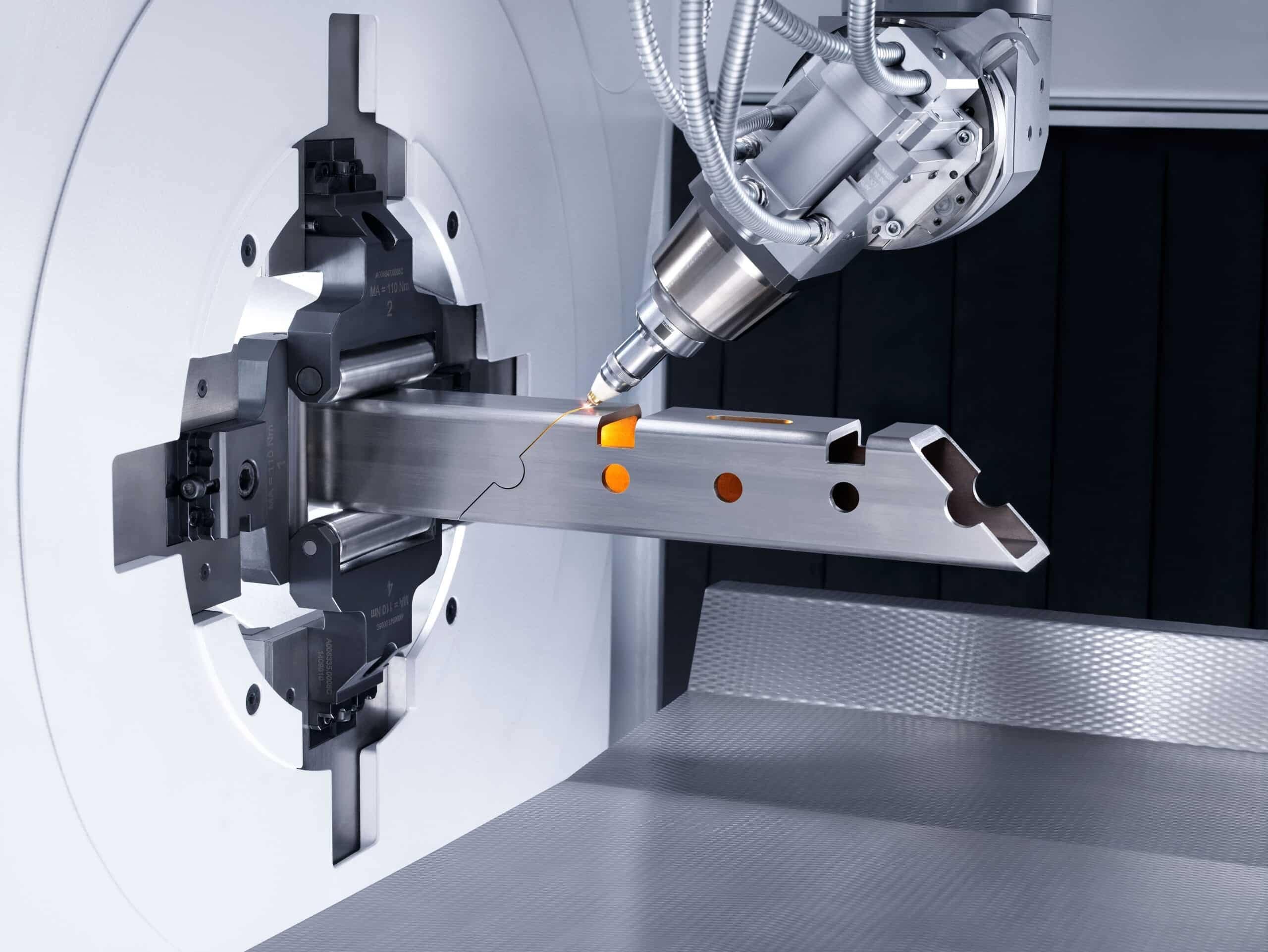

We’ve always been at the forefront of 3D laser cutting technology, continually investing in the latest 3-dimensional cutting machines means we have the capacity and versatility to cut more than just lengths but also complex shapes and holes. However, increasingly important for our clients, is our ability to cut the ends of the section for weld preparation with bevels and chamfers in angles up to 60 degrees.

Multi-axis 3D lasers have helped many of our clients reduce labour time, lower costs and increase efficiency, this is achieved in two ways: Firstly due to the precision cuts provided by the lasers, to a standard unachievable by manual processes, and secondly, the laser cutting process can cut the metal without applying mechanical force, meaning there is no warping or material deformation. Improving the product fit and appearance and reducing the chance of rejected parts.

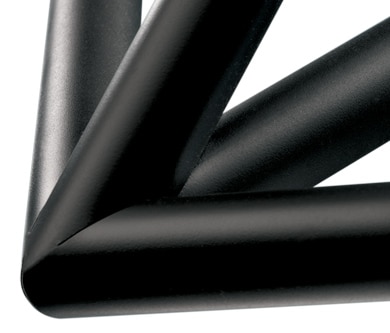

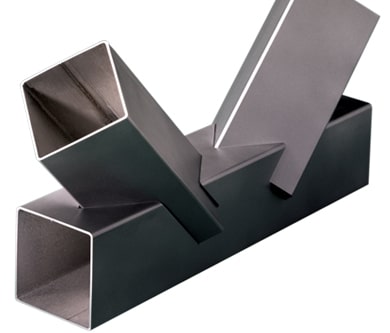

These two features guarantee a full bearing surface onto the adjacent section, thus efficiently transferring compressive loads. This could avoid the use of full penetration butt welds in such situations, creating savings in both time and cost during the fabrication process.

We work with customers to determine the most cost effective way of processing steel, aluminium and stainless open and hollow sections to achieve overall savings. By utilising our 3D laser cutting services we can remove many of the problems associated with processing sections in the fabrication shop, leaving the fabricator to utilise labour more effectively.

Get in touch today for more 3D laser cutting information

Laser Cutting 3D Section

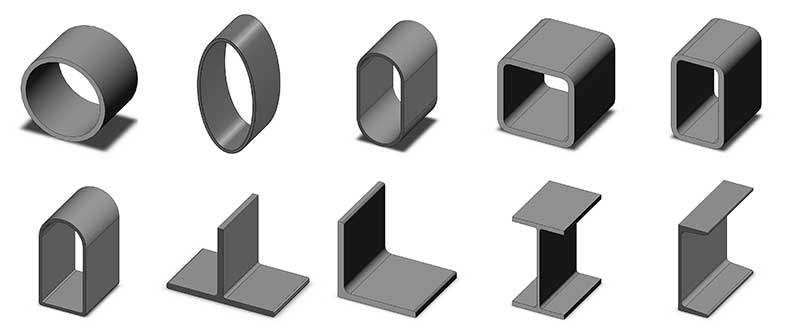

Between our Mazak and BLM CNC laser machines, we are able to process a wide range of different hollow sections (tube, box, rectangle etc.) and open sections (angle, beams, channel etc.).

The below image highlights some of the common section profiles we laser cut on a regular basis. For more specific information, our sales team will be happy to answer your questions.