The Laser Cutting Company

Sub-contract Laser Cutting Service

We invest in the latest cutting and profiling technologies, so you don’t have to.

Established in 1981, The Laser Cutting Co. has evolved into a complete outsourced metal profiling and laser cutting service. From our Sheffield headquarters we provide a one-stop-shop, delivering unrivalled manufacturing efficiency and quality.

Laser Cutting Co. customers benefit from aggregated buying prices and rapid turnaround times. 24-hour lights-out production and a suite of 10 laser cutting machines ensure projects of all sizes and levels of complexity are accommodated with ease.

Eliminate the need for time-consuming weld preparation with 45° bevel and countersinking on both outer and inner contours. Flow drill and tapping services ensure Laser Cutting Co. customer orders are delivered fully prepared and ready for assembly.

Efficiency

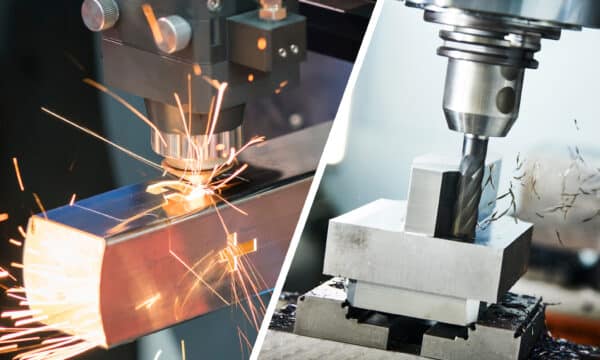

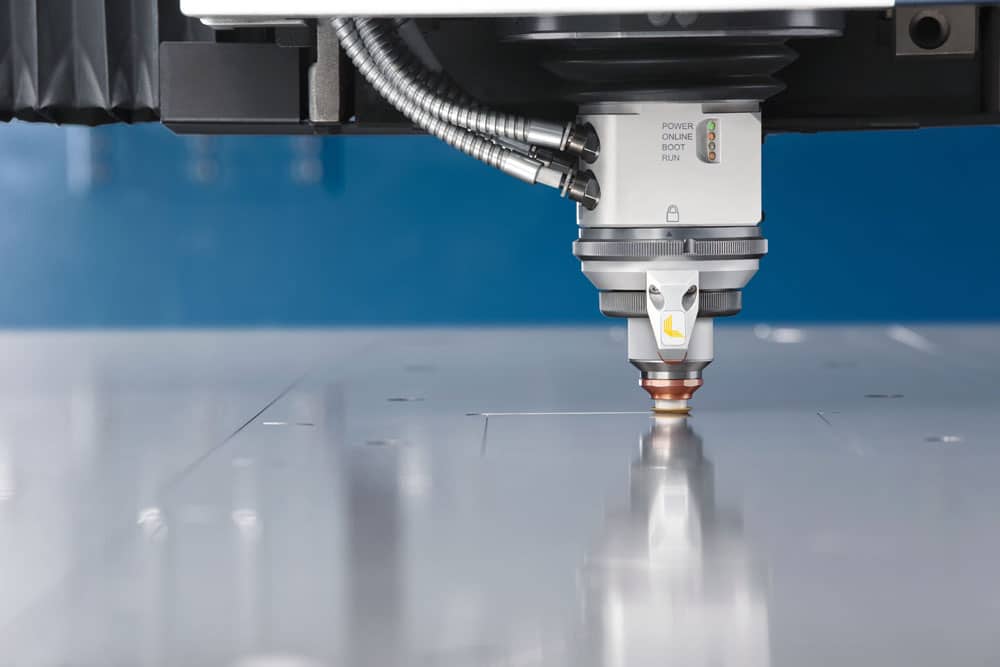

CNC fibre laser cutting machines operate 24-hours a day for rapid lead times at competitive prices.

Quality

ISO9001 and BS/EN 1090-1 accredited service delivers reliable quality on the largest and most complex projects.

Experience

Over 40 years’ laser profiling experience using the latest cutting technologies. Our investments, your benefit.

Tube Laser Cutting

Sheet Metal Cutting

Laser Profile Cutting

Bevel and Countersink

Flow Drilling and Tapping

Metal Forming

Smart Design Production

Additional Services

What Metals Can be Laser Cut?

We profile an extensive range of metal and non-metallic materials. With four different flatbed cutting methods under one roof, we can cut materials at depths between 0.1mm and 270mm. If a particular material is not in our exhaustive inventory, we can typically source it within 24-48 hours.

Quality Assurance is at the heart of what we do

The Laser Cutting Co.’s Quality Promise

The highest possible quality standards with the after sales support to match

Our Factory Production Controls are in accordance with legally enforceable construction product regulation BS EN 1090 – Level 3, allowing intricate cutting of construction regulation profiles

Certified to BS EN ISO 9001:2015 for all profiling requirements

Laser Cutting FAQ's

What is laser cutting?

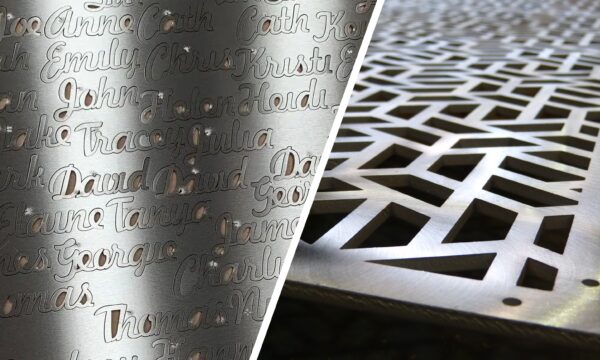

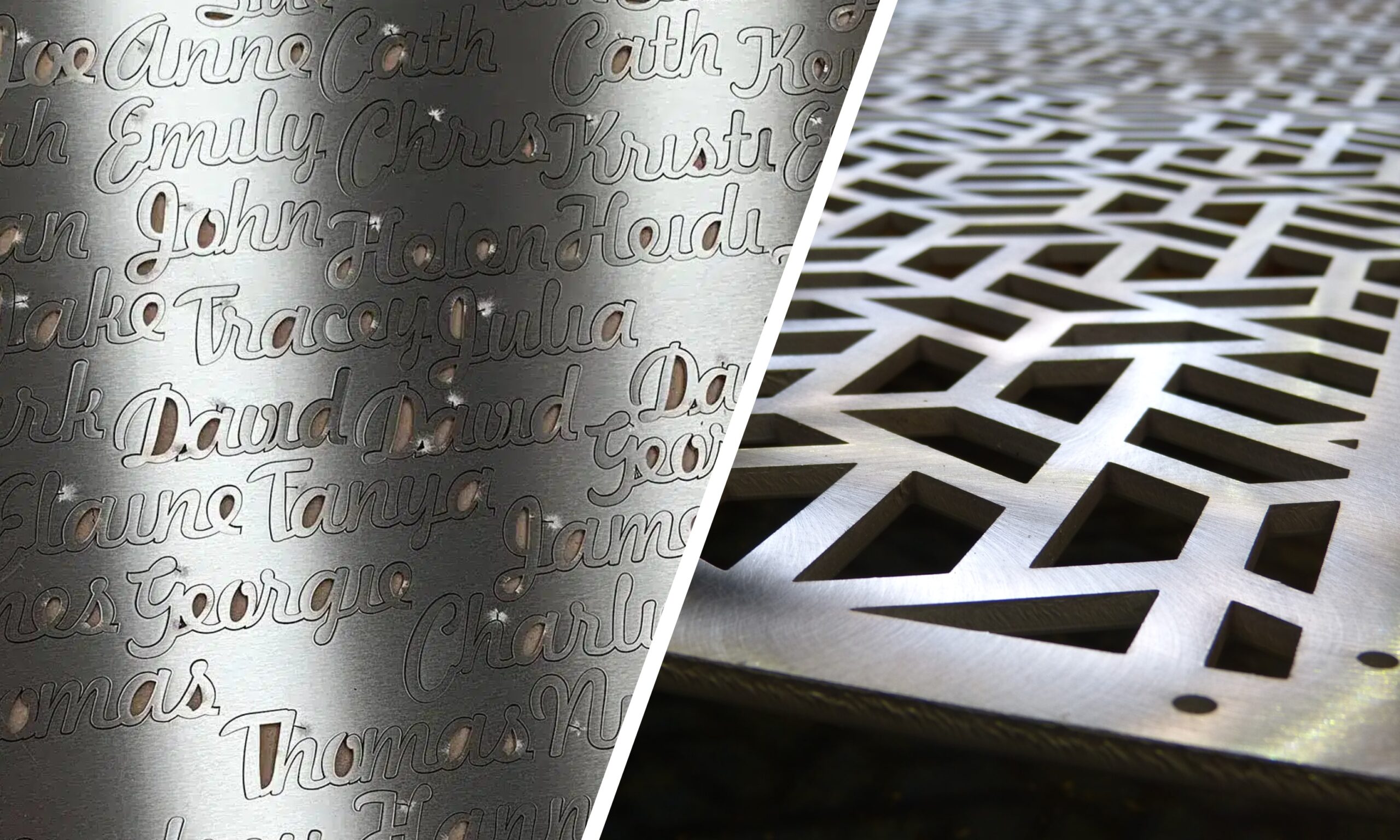

Laser cutting is a method of metal cutting that uses a high-powered laser to vaporise and cut metal. Laser Cutting is most commonly used for industrial applications, but can also be used to create bespoke laser etching and engraving.

What materials can be laser cut?

A multitude of materials can be laser cut to suit a range of purposes and applications, including a range of metals.

What materials can’t be laser cut?

Although the majority of materials can be laser cut, some materials are not recommended for laser cutting. Some of these materials include fibreglass, polycarbonate, PVC and HDPE.

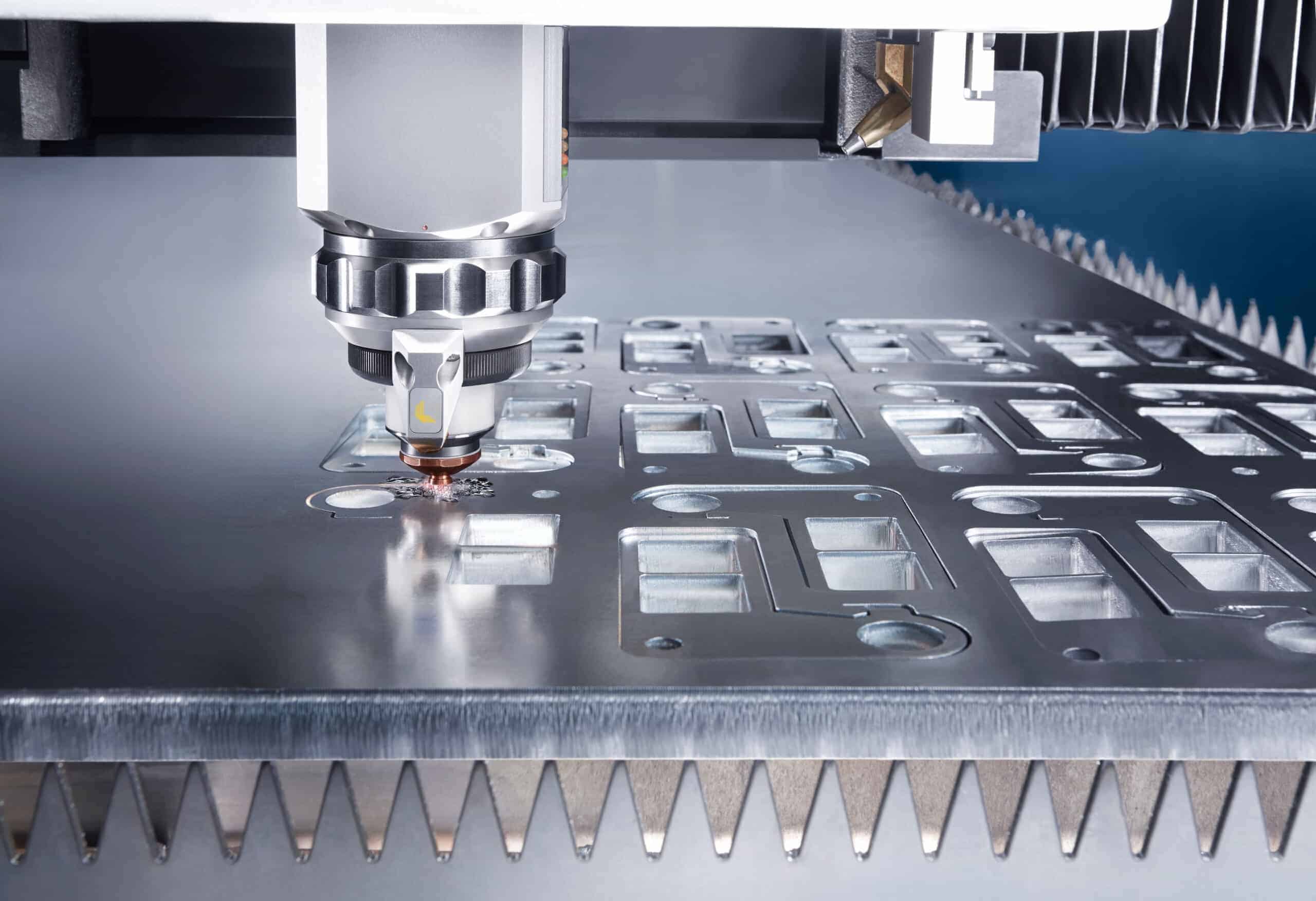

How does laser cutting work?

Laser cutting involves focusing a laser beam through a lens onto the material to be cut. The intense heat of the laser beam melts or vaporizes the material along the desired cutting path, creating a narrow kerf. Computer-controlled movements guide the laser beam, allowing for intricate and precise cuts.

What are the advantages of laser cutting?

There are several advantages to using laser cutting, some of which include:

- Cuts non-ferrous materials easily

- Rapid turn around

- Can cut through metals up to 50mm thick

Capable of cutting highly-detailed and precise shapes

Are there any limitations to laser cutting?

Although there are a plethora of benefits to laser cutting, it requires a significant amount of money to maintain. This is one of the many reasons why we here at The Laser Cutting Co. invest in the best and most advanced laser cutting technology, so our customers don’t have to; saving considerable costs whilst still providing a premium quality product.

How much does laser cutting cost?

The costs of laser cutting can vary greatly depending upon certain factors, including materials, the time required for cutting, level of detail, delivery, and labour. Here at The Laser Cutting Co., 24-hour production paired with our suite of industry-defining laser cutting machines ensures that we are able to provide incredible lead times and provide thorough and cost-effective solutions.

For a bespoke laser cutting quote, get in touch with The Laser Cutting Co. today.

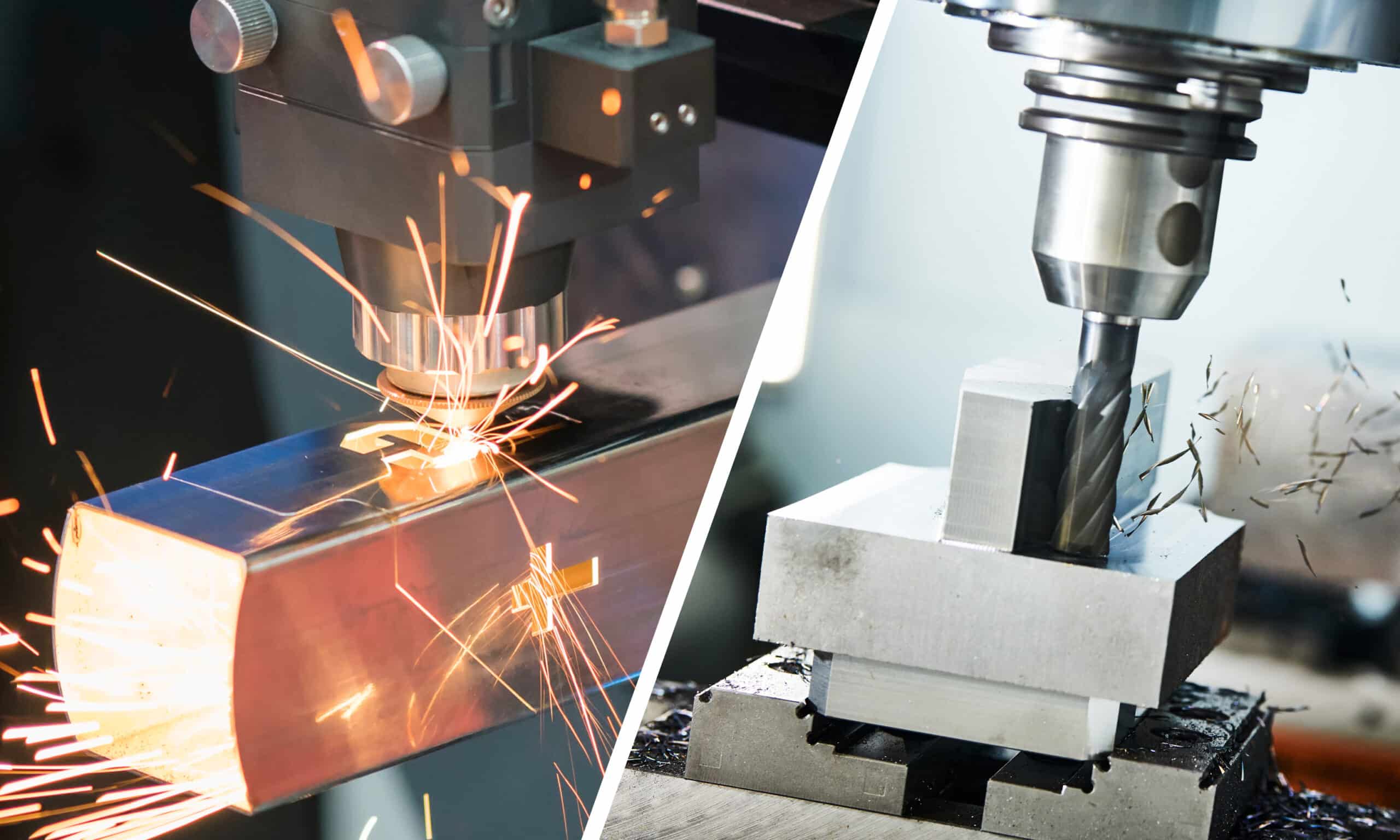

What are the main types of laser cutting?

The three major types of laser cutting include:

- Fusion Cutting – a cutting technique that cuts metal by melting them and then blowing out the molten remnants using a high-pressure stream of inert gas.

- Remote Cutting: involves cutting very thin and delicate materials without the use of gas, as the laser itself is able to evaporate the material away.

What are 8 processes of a laser cutter?

Laser cutters are capable of the following…

- Perforating

- Cutting

- Etching

- Seaming

- Engraving

- Welding

- Marking

- Drilling

How precise is laser cutting?

The kerf of a laser cutting machine is considerably thinner than the kerf of a sawblade, so is therefore capable of extremely detailed and refined cutting when compared to other methods of material cutting; with a cutting tolerance of +-0.25mm.

What is the maximum size and thickness for laser cutting?

At The Laser Cutting Co., our laser cutting tolerances are unrivalled. With our professional suite of laser cutting machines, we are able to process sheet metal sizes up to 2500mm x 6000mm, and up to 50mm thick.